Scene 1 (0s)

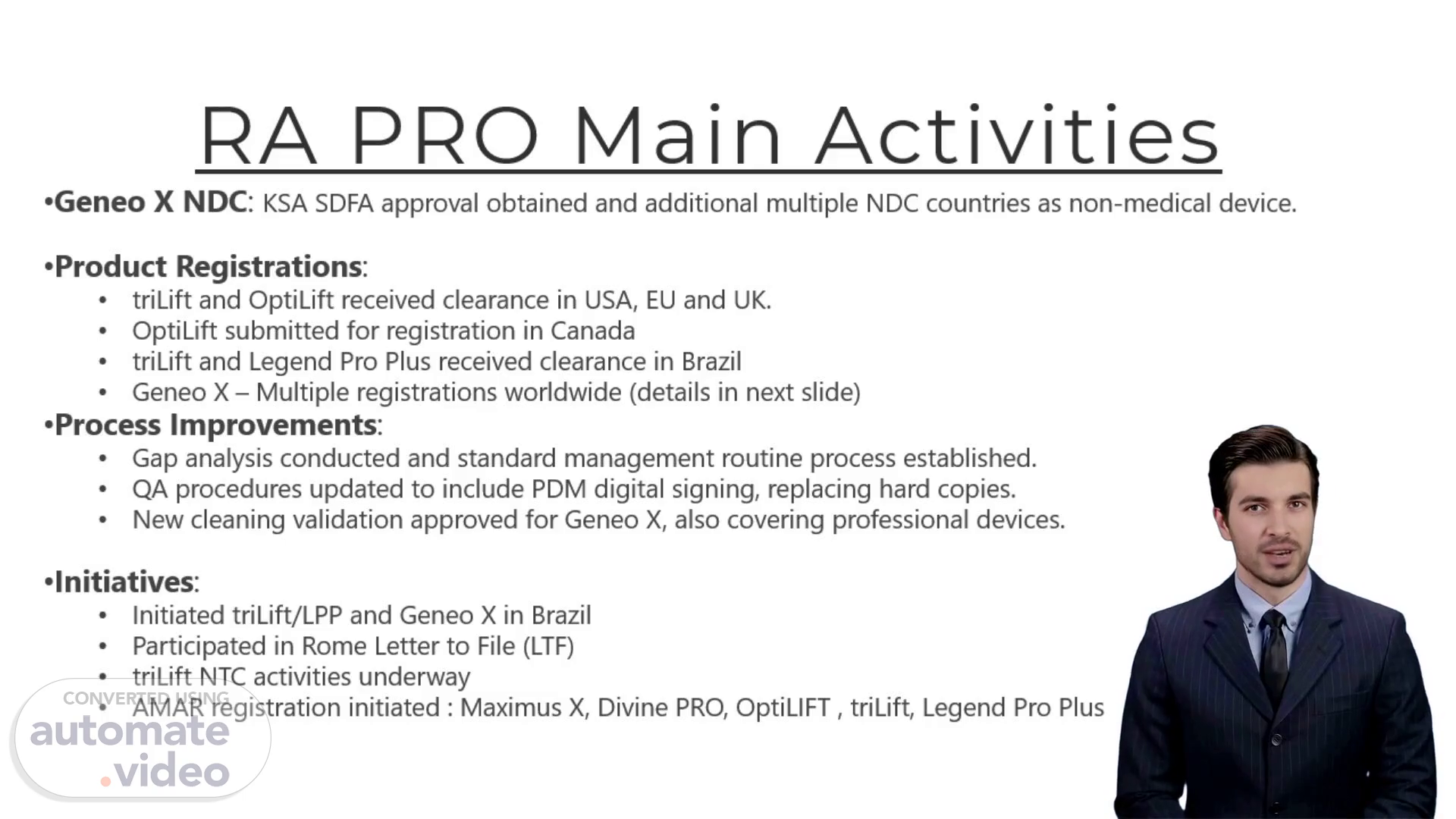

[Virtual Presenter] Today, we will be discussing the main activities of the RA PRO department. As shown on the screen, our company has received approvals for multiple product registrations in various countries. Process improvements have also been implemented, including a gap analysis and standard management routine process, to ensure our products meet high quality standards. We have also launched new initiatives, such as product registrations and participation in letter to file activities. Our triLift and OptiLift products have been cleared in the USA, EU, and UK, and we have submitted OptiLift for registration in Canada. In addition, both triLift and Legend Pro Plus have received clearance in Brazil. Our Geneo X product has also received multiple registrations worldwide, which we will discuss further on the next slide. We have also conducted a comprehensive gap analysis and established a standard management routine process to identify areas for improvement and ensure compliance with regulations. We have also updated our QA procedures to include digital signing and implemented a new cleaning validation for Geneo X. Furthermore, we have launched triLift/LPP and Geneo X in Brazil and participated in the Rome Letter to File (LTF) triLift NTC activities. We have also begun the process for AMAR registration for products such as Maximus X, Divine PRO, OptiLIFT, triLift, and Legend Pro Plus. Thank you for your attention and please stay tuned for the next slide, where we will discuss the details of our Geneo X registrations..

Scene 2 (1m 44s)

[Audio] In the previous slide, we discussed the progress of our company in terms of product approvals, process improvements, and new initiatives. Now, let's focus on our ongoing and future projects and engineering changes. Our current projects include the GENEO X RFID, which has received 510K and Canada submissions. We are also addressing cybersecurity and wireless radio communication requirements. Moving forward, we have two upcoming projects - GENEO X Frac-Lite and ECHO RESSISTIVE. These projects will be submitted in Israel and Europe, and will go through 510K, NDC, and Canada submissions. We have several other projects in progress for the next phase. Along with these projects, we have ongoing engineering changes such as letter-to-file activities, annual notifications in Canada, and updates to our technical files. It is crucial for our team to stay on top of these projects and changes as they will greatly contribute to the success of our company. Thank you for viewing this slide and be sure to check out the next slide for more important information..

Scene 3 (2m 57s)

[Audio] On slide number 3, we will discuss recent achievements of the company. The company has received approvals for multiple products in various countries. This allows for expansion and availability of our products to a larger global market. Additionally, process improvements have been implemented to ensure high-quality and efficient operations. The company has also taken on new initiatives, such as product registrations and participation in compliance activities, showcasing our commitment to providing safe products for consumers. Moving on, Geneo X has completed new international registrations in several countries such as Israel, Peru, Argentina, and more, and is currently in the process of registering in new territories and with new distributors. These international registrations are essential for the company's growth and success in the global market. In summary, the company's recent achievements and efforts in international registrations demonstrate a dedication to providing high-quality products and expanding our presence in various countries. We will continue to strive for excellence and maintain the highest standards for the benefit of our customers. Stay tuned for the next part of the presentation..

Scene 4 (4m 18s)

[Audio] Slide number 4 of our presentation discusses the regulatory milestones and challenges our company has faced. Throughout the past few years, we have achieved approvals for multiple products in various countries and implemented process improvements to operate more efficiently and effectively. This has allowed us to better serve our customers and meet their needs. We have also undertaken exciting initiatives, such as product registrations and participation in letter to file activities, which have expanded our reach and allowed us to offer our products to a larger market. In particular, our company has been inspired by the China Regulatory Milestones, with our product successfully classified as a non-medical device for the nourish mode by the NMPA. Another significant milestone for our company is the Echo-Resistive technology Medical RF device, TRX100, which has been submitted for NMPA clearance in March 2026. Our continuous efforts towards product development and improvement have led to this major achievement. We take pride in our regulatory compliance with regions such as Europe, USA, Canada, and Japan, with our products AURA, IMPRESS, STOP VX2, STOP VX2 GOLD, and PRISM all meeting regulations in these areas. However, we do face challenges with regulatory classification, as the same product may be considered non-medical in one region and a medical device in another. This requires us to adapt our regulatory paths accordingly. An exciting project for our company is the OptiLuv for Dry Eye, which has been submitted for 510K review under the FDA. This home-use product is expected to be well-received by our customers. Lastly, we are pleased to announce that our company has completed the registration of our Activator Gel in the EU, UK, and USA for our Global Cosmetics line. This is a significant achievement for us and will allow us to expand our market..

Scene 5 (6m 27s)

[Audio] Slide 5 discusses our company's efforts in ensuring high quality products and processes. These efforts have resulted in obtaining approvals for multiple products in different countries, implementing process improvements, and initiating new initiatives such as product registrations and participating in letter to file activities. A key aspect of our quality practices is providing support and audits to our suppliers and subcontractors, including companies like Ace-Tech, STH, ENG, Solex for Home-Use, and Arnir, Flex, T. Golan, RafiMed, Mediplast for PRO. This guarantees that all our products and processes meet the highest quality standards. We also offer ongoing support for all quality matters, including handling device malfunctions under service calls, conducting thorough investigations, and implementing corrective and preventive actions. This ensures the quality of our products even after they are sold to customers. We also extend our support to the establishment of our production line and process validation for new products and subcontractors. This involves working with companies like GX cart, OptiLift in Arnir, Geneo X NDC at SLC, and Geneo X at RH USA, allowing us to maintain consistency and high quality standards across all our products and processes. We are proud to share that our efforts have been recognized through successful DEKRA and MDC audits. We have obtained MDSAP and ISO certifications and passed the MDC audit for EU MDR with zero nonconformities, highlighting our dedication to maintaining the highest quality standards. Our quality assurance and management practices go beyond audits and inspections, with ongoing QA and QMS activities such as QA procedures, handling customer complaints, implementing corrective actions, performing calibrations, conducting management reviews, and monitoring KPIs. We also ensure that all necessary documents are approved through our PDM system. With our robust quality measures in place, we have confidence in the quality of our products and processes..

Scene 6 (8m 47s)

[Audio] As we come to the end of this training video, let's focus on slide number 6. This slide highlights our company's recent accomplishments, specifically in terms of audits, inspections, device malfunctions and CAPA, and product development. Firstly, we have received approvals for multiple products in different countries. This is a significant achievement as it expands our product's reach and increases our presence in the market. In addition, the implementation of process improvements is essential in ensuring the highest quality of our products. Not only does this benefit our customers, but it also showcases our dedication to continuous improvement. Moreover, our company has taken the initiative to conduct audits at subcontractors, ensuring that their processes align with the ISO 13485 standards. Any corrective actions identified during these audits are promptly addressed to maintain compliance and quality. Inspecting and supervising our products at various sites, including end-of-production and plastic parts inspections, is crucial for ensuring their safety and functionality. Regarding device malfunctions and CAPA, our company has demonstrated a proactive approach by handling malfunctions during service calls and on the production line. This not only addresses any issues promptly, but also implements corrective actions to prevent future malfunctions. Finally, our company's dedication to product development is evident through the creation of a V&V list for each new product. By consolidating all device tests and requirements, the development stage becomes streamlined and ensures the highest quality from the beginning. In conclusion, our recent achievements in audits, inspections, device malfunctions and CAPA, and product development showcase our commitment to excellence and continuous improvement. Thank you for listening, and I hope this training has provided valuable insights for your work in Higher Education..