Scene 1 (0s)

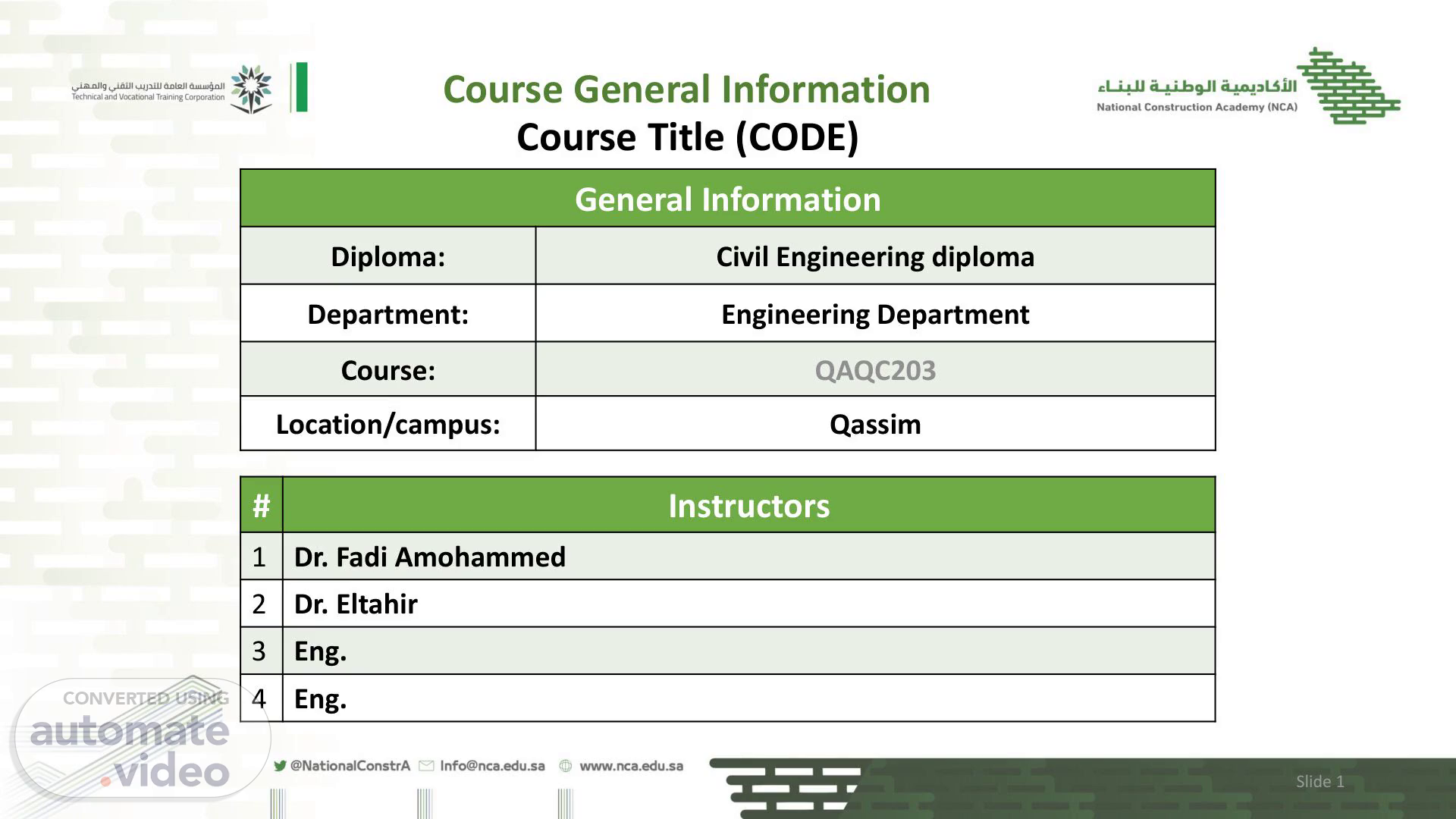

Course Title (CODE) # Instructors 1 Dr. Fadi Amohammed 2 Dr. Eltahir 3 Eng. 4 Eng. General Information Diploma: Civil Engineering diploma Department: Engineering Department Course: QAQC203 Location/campus: Qassim Slide 1 Course General Information.

Scene 2 (12s)

Hours Credit (Total) Contact Theory Practical 2 - 28 - Delivery Methodology Comments 1. Traditional Classroom The classes will provide an explanation for the subject including, Instructor Explanation, Videos, Figures and interaction with students 2. Blended 3. E-learning Provide all the resources and the presentations on LMS with quizzes 4. Distance Learning 5. Other (specify) Visiting labs and site Slide 2 Course General Information.

Scene 3 (29s)

Course Description This course provides a comprehensive exploration of Quality Assurance (QA) and Quality Control (QC) principles and practices specifically tailored for the field of civil engineering. Students will gain a deep understanding of the methodologies and tools used to ensure that civil engineering projects meet or exceed the required standards and specifications. Slide 3 Course General Information.

Scene 4 (45s)

Learning Outcomes (LO): The trainee will: Assessment Criteria (AC): The trainee can: Knowledge & Understanding (Theoretical) LO1. Understand the QA/QC principle LO2. Application of Standards and Regulations LO3. Implementation of Quality Management System LO4. Conducting Inspections and Testing LO5. Effective Documentation and Reporting LO 6. Understanding of Quality Control principles and processes AC1- Understanding what is the roles and responsibilities for QA/QC AC2- Applying and Understanding international standards ISO AC3- Understand the quality management system AC4- Applying different tests in different labs with doing an inspection AC5- Understanding the important documents of the QA/QC, reading and applying them. AC6- Identifying the principles and processes for Quality Control Skills (Practical): Slide 4 Course General Information.

Scene 5 (1m 14s)

Learning Outcomes (LO): The trainee will: Assessment Criteria (AC): The trainee can: Knowledge & Understanding (Theoretical) LO 7. Ability to identify and analyses defects in construction project LO 8. Ability to develop and implement quality control plans LO 9. Understanding of statistical process control and process capability LO 10. Knowledge of root cause analysis and corrective action LO 11. Ability to develop and maintain quality control documentation and reports. LO 12. Understanding of quality control standards and regulations LO 13. Ability to develop and implement quality control systems AC7- Identify and Analysis defects in construction projects AC8- Develop and implement quality control plans. AC9- Using the statistical Quality Control Tools: check sheet, cause and effect diagram, flow chart, histogram, pareto chart analysis and control chart. AC10-Prepare the root cause analysis and corrective action. AC11- Write and Prepare quality control documentation and reports. AC12- Using and discussing Quality Control standards and regulation AC13-Prepare the quality control systems Skills (Practical): Slide 5 Course General Information.

Scene 6 (1m 54s)

Course General Information ASSESSMENT SCHEDULE week Date Assessment Description Learning Outcomes Assessment Criteria Grade Percentage Week 6 Assessment 1 Reports, Paper or lab-based Exam 25 Week 11 Assessment 2 Reports, Paper or lab-based Exam 25 Quiz Lab, paper based 10 Week 15 Assessment 3 Final Project, Presentation 35 Participation 5 100% Slide 6.

Scene 7 (2m 6s)

QA/QC -203 Unit 10: Page: QA/QC Roles and Responsibilities 1 24.

Scene 8 (2m 14s)

All objectives related to lesson content should be listed here Lesson Objectives Slide 8.

Scene 9 (2m 22s)

Definitions • Quality Control (QC): The operational techniques or a system of maintaining standards by reviewing, checking, inspecting and testing. • Quality Assurance (QA): The planned and systematic actions and implementations necessary to provide adequate confidence that the work will satisfy quality requirements 9.

Scene 10 (2m 37s)

Definitions • Quality System (QS): A set of documented processes, which seek to provide satisfaction that the project outputs will fulfill all the requirements for which it is being planned • The quality system should fully incorporate the organization, human resources, materials, requirements, processes, inspections, testing and other parameters of the project. A key element of QS is the QA/QC Manual. 10.

Scene 11 (2m 56s)

Definitions • Quality Surveillance: • This normally covers two aspects. • At the project level, a review is required to ensure that the quality practices are implemented and documented to ensure in relation to the quality system • At the contract package level, inspection and testing is required to ensure that the works executed meet the required quality standards 11.

Scene 12 (3m 13s)

Click to edit Master title style • This QA/QC manual focuses on the implementation activities of the project following contract award, primarily on supervision and quality control of construction works it will provide a base outline towards, procedure, responsibility, compliance acceptance criteria and documentation for carrying out inspection, testing and reporting on various materials. • The QA/QC Manual for the construction activity does not attempt to suggest technical specifications, since these are stated in the contract documents. 12.

Scene 13 (3m 36s)

Click to edit Master title style • Site documents • Mandatory and optional testing • Availability of field and departmental laboratories • Manufacturing test certificates • Department team inspections 13.

Scene 14 (3m 46s)

• Checklist guide for works • Site inspections • Post quality testing of finished works • Quality certification • Monthly reporting and review meeting.

Scene 15 (3m 55s)

Click to edit Master title style • Display of Notices • Warning tape, lighting arrangement at location of any excavated trench, electrical installation or mechanical erection • Fire prevention and protection • Environment & Health 15.

Scene 16 (4m 7s)

• House keeping • Lighting • Noise and Vibration • Personnel Protective equipment (PPE) for field staff.

Scene 17 (4m 15s)

Click to edit Master title style ❖Design/Drawings for contract: • Maintain design/drawing register at site • Use only approved drawings for construction ❖Test laboratory and equipment: • Intimate the details, date of completion with requisite manufactures, and calibration certificates of equipment. • Maintain the equipment in good condition and calibrate as necessary. 17.

Scene 18 (4m 32s)

Click to edit Master title style ❖Material receipts Materials testing: • Enter receipts in material register • Materials to be tested only in approved laboratories • Prepare concrete mix proportions as per volume as required by contract and submit test results • Take test samples in presence of QC when requested • Perform material tests • Submit test reports to QC with monthly reports 18.

Scene 19 (4m 49s)

Click to edit Master title style ❖Rejected Materials: • Entries to be made in material register at site • Tag and record all rejected materials • Intimate QC in writing the proposed date of removal of material from site and confirm after removal 19.

Scene 20 (5m 2s)

Click to edit Master title style ❖Material consumption: • Enter daily consumption of material in material register and indicate balance quantity ❖Construction equipment: • Intimate owner the details, date of mobilization along with requisite insurance certificate • Maintain equipment in good working condition • Intimate breakdown of construction equipment 20.

Scene 21 (5m 17s)

Click to edit Master title style • Intimate owner in writing when construction is going to commence and what activities are proposed to be undertaken • Intimate owner in advance when critical works, such as concreting, embankment, paving, pipeline laying and jointing, testing, etc., would be undertaken, along with the test certificates of the materials proposed to be used in these works. No critical activity shall start unless the material is tested. Certificates are verified and approved by the engineer. • Concreting to take place only after pour card is signed • To provide any other necessary QA/QC requirement 21.

Scene 22 (5m 44s)

Click to edit Master title style ❖Daily Work Progress: • To maintain in daily log ❖Testing of works in progress: • Perform tests as per contract requirements • Submit test report to QC • Maintain test log during the execution of works. 22.

Scene 23 (5m 57s)

Click to edit Master title style ❖Rejected work items: • Intimate GPWSC/DWSS in writing the proposed date removal site and confirm after removal. • Rectify defective work and invite QC for re-inspection ❖Instruction from engineer • Enter change orders, site instructions, letter and minutes of meetings issued by the engineer and consultants in the instruction log. 23.

Scene 24 (6m 14s)

Click to edit Master title style ❖ Inspection of Engineer: • Take instructions in site Order BOOK. • Intimate QC of compliance ❖ Progress scheduling and control: • Prepare and maintain project schedules and undertake work in accordance with approved schedule ❖ Reporting: • Prepare and submit Monthly Progress Reports and other reports as per contractual requirements. 24.

Scene 25 (6m 31s)

Click to edit Master title style ❖Records: maintain the following records on sit/contractor’s Office/Laboratory • Site Order Book • Material Register • Daily Progress Report • Concrete Pour Register 25.

Scene 26 (6m 42s)

• Test Record • Design & Drawing Record • Non Conforming item Record • Cube Test Record.

Scene 27 (6m 50s)

Click to edit Master title style ❖Workmanship: • All the work executed against the contract shall be of good workmanship ❖Disposal of Debris: • All of Debris should be disposed of properly after completion of construction work 27.

Scene 28 (7m 2s)

Click to edit Master title style ❖Mandatory Testing: • Cement • Fine Aggregate • Coarse Aggregate • Concrete (Slump, Cube test) • Steel bars 28.

Scene 29 (7m 12s)

• Bricks • Timber • Hydro testing of sewer • Hydro testing of pipe • Water for construction.

Scene 30 (7m 20s)

Click to edit Master title style ❖Availability of Field and Alb Equipment, Manufacturing Certificates: • Cement • Steel for reinforcement and structural steel • GI Pipe/ GI Fitting/ PVS/ MS/ SW/ RCC Pipes • Manhole covers and Footrest • Ac/ GI/ Fiber glass sheets 30.

Scene 31 (7m 35s)

• Electrical cable/ Sockets and Boards • Flow measuring devices • Control Panel • Lightening arrestor • Level indicator and controllers • Silver ionization plant • Any other item as per agreement.

Scene 32 (7m 45s)

Click to edit Master title style • Periodical Site Inspections • Post Quality Inspection of Finished Works • Quality Certification • Monthly Reporting and Review Meeting 32.

Scene 33 (7m 55s)

Click to edit Master title style • Planning Technology Selection • Procurement • Construction • Management & full Financing of O&M 33.

Scene 34 (8m 3s)

Click to edit Master title style • The visit of all the representatives • Any dispute which have arisen during the day, and particularly any verbal instruction he gave as a result • Any practical points regarding the work which he does not necessarily raise with the contractor at present • Any notes regarding particular stages of work or carried out 34.

Scene 35 (8m 20s)

Click to edit Master title style ❖The register can consist of a ruled book which has columns ruled vertically, headed in sequence from the left to right across both pages as follows: • Sample number • Source • Location • Description (brief only) 35.

Scene 36 (8m 33s)

• Depth • Date taken • Where tested • Remarks/references.

Scene 37 (8m 40s)

Click to edit Master title style • Construction Quality Control (CQC) is intended to provide a comprehensive, common and consistent framework for quality control across various contract packages. CQC comprise two main elements of quality control” • Testing • Inspection 37.