Scene 1 (0s)

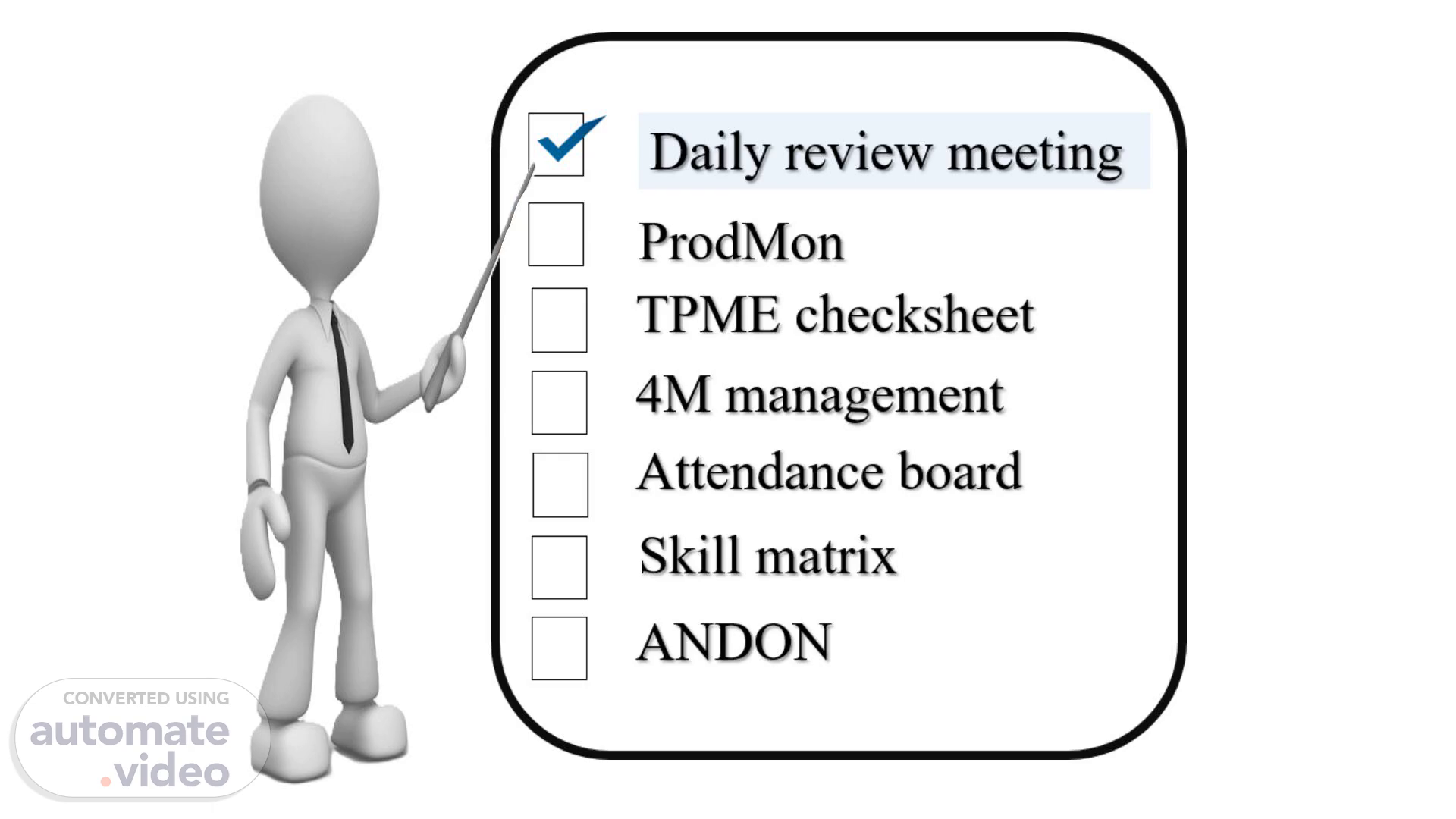

[Audio] Our daily review meeting will cover key aspects of our production monitoring system, including four-M management, attendance tracking, skill assessments, and ANDON reporting. We will discuss how these elements work together to ensure efficient and effective operations. Let's take a look at our agenda for today's meeting..

Scene 2 (4s)

[Audio] The daily review meeting is crucial in ensuring a smooth transition between shifts. During this meeting, the incoming Hancho will discuss key operational matters with the outgoing Hancho and line leader. This includes reviewing quality control issues and discrepancies, addressing production challenges and downtime, and inventory management concerns such as missing or depleted raw materials. By doing so, we can identify potential problems early on and take corrective actions to minimize their impact..

Scene 3 (20s)

[Audio] The daily review meeting discusses the current state of our production monitoring system, examining key performance indicators such as 4M management, attendance board, skill matrix, and ANDON. We assess how these metrics impact our operations and identify areas for improvement. This meeting ensures everyone is aligned and working towards common goals..

Scene 4 (24s)

Start ProdMon session and update data.

Scene 5 (28s)

Set production plan in the Production analysis board and ProdMon.

Scene 7 (1m 1s)

[Audio] We closely monitor the production line's performance through hourly tracking. Every hour, we track the output to ensure smooth and efficient processes. This data enables us to identify any issues or bottlenecks that may emerge during the day. By analyzing these numbers, we can take corrective actions to maintain our high standards of quality and productivity..

Scene 8 (1m 33s)

[Audio] The daily review meeting discusses the current state of the production monitoring system, examining key performance indicators like 4M management, attendance board, skill matrix, and ANDON. These metrics are reviewed to identify areas for improvement and adjust strategies accordingly. This meeting ensures everyone is informed about issues and works together to optimize production processes..

Scene 9 (1m 38s)

Inspection of TPME checksheet.

Scene 10 (1m 42s)

[Audio] The daily review meeting assesses our progress against our targets, ensuring we are on track to meet our goals. We evaluate our performance using the 4M management framework, reviewing attendance records, skill matrices, and ANDON reports to identify areas for improvement. This meeting helps us stay focused on what matters most, making adjustments as needed to optimize our operations..

Scene 11 (1m 46s)

Record and visualize the change on 4M transition board.

Scene 12 (2m 14s)

Attach a change point indication tag to the first three products..

Scene 13 (2m 18s)

[Audio] The operational license has been granted to BOULEIMA AYOUB with the ID 29033. The license type is MCRMP, and its expiration date is February 25th. Furthermore, there is another license called SETTER, which is also set to expire on August 25th..

Scene 14 (2m 23s)

Develop the correct competencies and behaviors of the operators during OJT..

Scene 15 (2m 28s)

Monthly report all OLS related tasks..

Scene 16 (2m 41s)

[Audio] We reviewed the daily production monitoring report, highlighting key performance indicators and identifying areas for improvement. The 4M management system tracks and analyzes our progress towards our goals. Our attendance board showed who was present during the shift, while the skill matrix helped us identify training needs. Any issues or concerns were reported through the ANDON system. This comprehensive review enabled us to make data-driven decisions and optimize our operations..

Scene 17 (2m 45s)

Display license badges on the Attendance board.

Scene 18 (3m 17s)

identify absent operators.

Scene 19 (4m 57s)

[Audio] We review our 4M management, attendance board, skill matrix, and ANDON reports during the daily review meeting to ensure we are on track to meet our goals. This discussion helps us identify areas for improvement and make necessary adjustments. By doing so, we stay focused on our objectives and maintain a high level of performance..

Scene 20 (5m 1s)

Monitor Poyvalence matrix : Skills Matrix Follow up & update.

Scene 21 (5m 26s)

[Audio] The daily review meeting discusses the current state of our production monitoring system, examining key performance indicators like 4M management, attendance board, skill matrix, and ANDON. These metrics are reviewed to identify areas for improvement and adjust strategies accordingly. This meeting ensures everyone is on the same page, working together towards common goals..

Scene 22 (5m 30s)

Ensure Andon usage.

Scene 23 (5m 35s)

Quick respond to the post where ANDON light is on, and deal with issues.