Présentation PowerPoint

Scene 1 (0s)

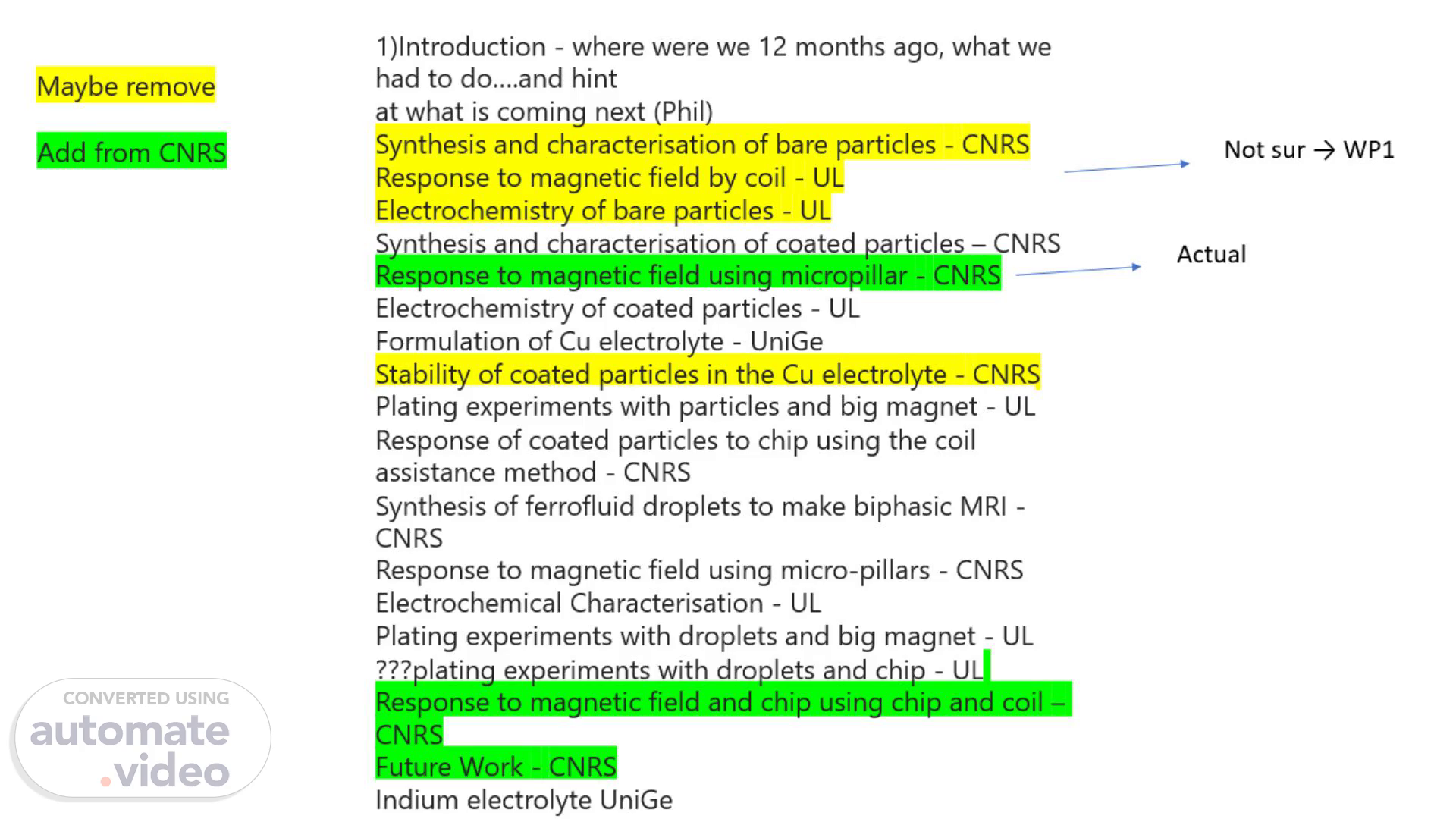

1. 1)Introduction - where were we 12 months ago, what we had to do….and hint at what is coming next (Phil) Synthesis and characterisation of bare particles - CNRS Response to magnetic field by coil - UL Electrochemistry of bare particles - UL Synthesis and characterisation of coated particles – CNRS Response to magnetic field using micropillar - CNRS Electrochemistry of coated particles - UL Formulation of Cu electrolyte - UniGe Stability of coated particles in the Cu electrolyte - CNRS Plating experiments with particles and big magnet - UL Response of coated particles to chip using the coil assistance method - CNRS Synthesis of ferrofluid droplets to make biphasic MRI - CNRS Response to magnetic field using micro-pillars - CNRS Electrochemical Characterisation - UL Plating experiments with droplets and big magnet - UL ???plating experiments with droplets and chip - UL Response to magnetic field and chip using chip and coil – CNRS Future Work - CNRS Indium electrolyte UniGe LMS Wrap - up summarising everything….. We still need to put in the protocol -.

Scene 2 (39s)

2. Introduction - where were we 12 months ago, what we had to do….and hint at what is coming next (Phil).

Scene 3 (49s)

[Audio] For this presentation we selected three different nanoparticle morphologies with similar nanoparticle coating On this slide you can follow the brief chemical route for obtaining these particles with chemical detailes provided in W-P-1 presentation We start with either iron salt coprecipitation method giving us spherical maghemite nanoparticles or polyol method giving us magnetite nanoflowers meaning that magnetite nanocrystals are « syntered » into larger flower-like nanoparticles. The reason for getting nanoflowers is that they should have higher magnetic moment than nanospheres keeping superparamegnetic behavior without remnant magnetization Then we coat nanopartcicles and nanoflowers by silica in order to render them electrochemically inert For nanospheres we use two different coating protocols giving us either thin silica layer around nanospheres or large silica nanocapsules with embedded iron oxide nanoparticles Only thin silica layer is used for nanoflowers After that we coat all the three types of particles by silane-jeffamine molecules in order to protect the particles agaist floculation under colloidal forces Finally we disperse the particles in a copper electrolyte whose composition was suggested by the partner from Luxembourg so at copper molar concentration of 0.01 molar and we adjust the particle concentration at 0.5 volume %.

Scene 4 (2m 18s)

[Audio] Here we briefly characterize the three types of particles with more detailed characterizations provided in W-P-1 presentation. We remind you that all particles are coated by silica and silane-jeffamine You see different morphologies of nanoparticles in these pictures: from more or less isolated nanoparticles (top right) to nanoparticles encapsulated into silica matrix (left) andnanoparticles synthered into nanoflowers (bottom right). The two most relevant parameters are hydrodynamic size (Z-average) and grafting density of silan-jeffamine chains The left value of the hydrodynamic size stands for water dispersions and the right values – for dispersions in electrolyte In all cases the hydrodynamic size is larger than that of individual nanoparticles or nanoflowers indicating some degree of colloidal flocculation However no any visible sign of sedimentation was observed for 1 month even for particles dispersed in electrolyte (to be confirmed later for nanocapsules) indicated a satisfactory colloidal stability/ Futhermore the hydrodynamic size in electrolyte (right values) are essentially similar (within analytical errors) to the values in water (left values) indicating that the polymer brush ensures similar protection against aggregation in media with low and high ionic strength The nanocapsules present the largest size on the order of 200 nanometers and this should be one of the hallmarks of nanopartcile encapsulation into larger silica matrix. What about the grafting density we get about 1 to 2 polymer chains per nm² of particles for nanospheres and nanocapsules n which is consistent with brush conformation of molecules on the surface Quite large value of 5 7 molecules/nm² for nanoflowers could come from incomplete elimination of non-grafted polymer at the end of the synthesis.

Scene 5 (4m 21s)

Institut de Physique de Nice A propos de l'EUR - Creates Institut de Physique de Nice.

Scene 6 (4m 56s)

6. Response to magnetic field by coil - UL.

Scene 7 (5m 4s)

7. Electrochemistry of particles - UL.

Scene 8 (5m 10s)

8. Formulation of Cu electrolyte - UniGe.

Scene 9 (5m 17s)

9. Plating experiments with particles and big magnet - UL.

Scene 10 (5m 24s)

10. coil Cooling bloc Pelter + INL chip + Kapton tape Water INL chip.

Scene 11 (5m 43s)

[Audio] Ici pour le schama de droite il faut pas oublier « the sample drop is placed onto the kapton tape and covered by a glass cover slip that is put on the top of the 150 µm thick spacers. Thus the sample thickness is about 150µm.

Scene 12 (9m 3s)

[Audio] To get biphasic electrolyte we first synthetized organic ferrofluid composed of oleic acid coated nanoparticles dispersed in dodecane The synthesis procedure is highlighted in WP 1 presentation. To get a microemulsion composed of ferrofluid droplets dispersed in water we used a microfluidic focusing method… bla-bla… Finaly before experiments the dropletts were transfered tothe copper electrolyte suggested by Luxembourg partner at 0.01 mol/L of copper concentration.

Scene 13 (10m 8s)

[Audio] To get biphasic electrolyte we first synthetized organic ferrofluid composed of oleic acid coated nanoparticles dispersed in dodecane The synthesis procedure is highlighted in WP 1 presentation. To get a microemulsion composed of ferrofluid droplets dispersed in water we used a microfluidic focusing method… bla-bla… Finaly before experiments the dropletts were transfered tothe copper electrolyte suggested by Luxembourg partner at 0.01 mol/L of copper concentration.

Scene 14 (10m 43s)

Une image contenant texte, capture d’écran, Police, Graphique Description générée automatiquement.

Scene 15 (13m 19s)

15. Electrochemical Characterisation - UL.

Scene 16 (13m 26s)

16. Plating experiments with droplets and big magnet - UL.

Scene 17 (13m 33s)

17. plating experiments with droplets and chip - UL.

Scene 18 (13m 40s)

Une image contenant art, grille, conception Description générée automatiquement t 0.3 I t coil 2 mT For separation.

Scene 19 (18m 40s)

Institut de Physique de Nice A propos de l'EUR - Creates Institut de Physique de Nice.

Scene 20 (18m 58s)

To be continued. 20.