Page 1 (0s)

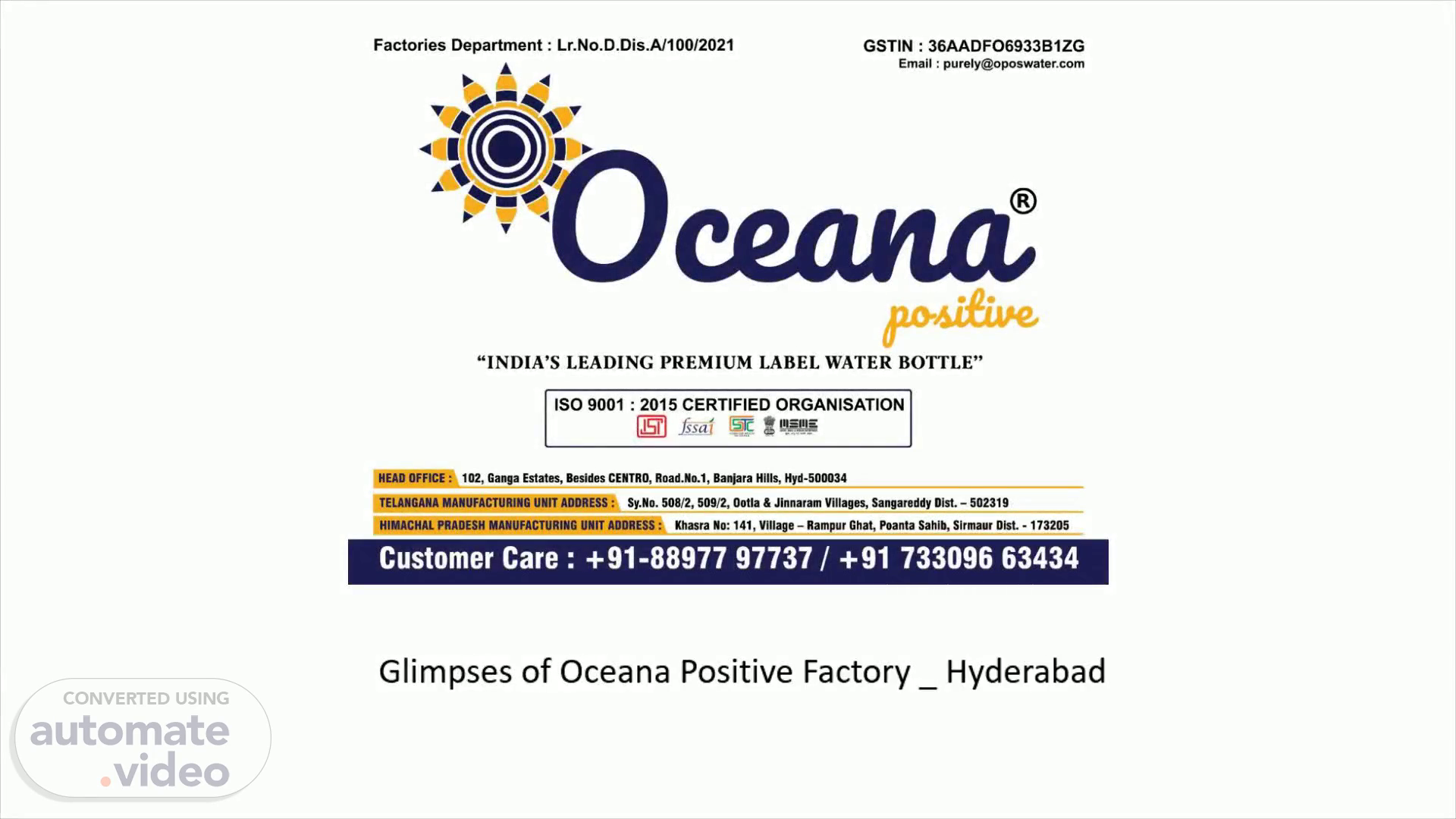

Glimpses of Oceana Positive Factory _ Hyderabad. Factories Department : Lr.No.D.Dis.A/100/2021 GSTIN : 36AADF06933BIZG Email : [email protected] "INDIA'S LEADING PREMIUM LABEL WATER BOTTLE" ISO 9001 : 2015 CERTIFIED ORGANISATION fssaf Ganga Estates, Besides CENTRO, Road.Nm1, Banjara Hills, Hyd-50w34 BELANGANA MANUFACTURING sy.No. 508/2, 509/2, ootia & Jinnaram Villages, Sangareddy Dist. - 502319 IMACHAL PRADESH MANUFACTURING UNIT ADDRESS/ Khasra No: 141, Village - Rampur Chat, Poanta sahib, Sirmaur Dist. - 173205 Customer Care : +91-88977 97737 / +91 733096 63434.

Page 2 (26s)

10,000 SFT Covered Area for production and 3000 SFT for ancillary purposes (like staff quarters, generator, staff dining, compressor yard, additional raw material room etc.) Total Extent of Factory : 3 Acres.

Page 3 (39s)

10,000 SFT Covered Area for production _ Factory Entrance View.

Page 4 (47s)

Factory Entrance View. Restricted permission Of management. entry only With 2. Please leave your foot wear outside prior NO Chewing gum NO chewing pan / 'gutka 3. Please wear cap, mask and Shoe covers before entering into the plant. 4. After visiting the toilets, please wash your hands & legs in KMN04 solution. 5. If you are suffering with fever, cold, cough, KMNOA open wound, diarrhea or any kind of 5.063 sickness please inform to the plant manager. 6. We can avoid many kinds of diseases, with 6.000 é0öéS good hygiene maintenance — kindly ensure 00006* öåoöo& shoe 8. Maintain silence when the production in 9. Regularly sanitize your hands. 10. the surroundings & and littering'. 10 Keep _ *fictlY.

Page 5 (1m 17s)

10,000 SFT Covered Area for production _ Factory Inside View.

Page 6 (1m 27s)

i 35 jil !jii. •nnn. Filtration Room View.

Page 7 (1m 34s)

/ Å&'Eå:'. 90 BPM RFC Room View. .Full' Automated (RFC) Line of Rinsing, Filling, capping, Labeling & Packing line with a production capacity of 5400 Battles per hour (1000.

Page 8 (1m 46s)

20 Litre Filling Area. • Fully Automated (RFC) hot water Rinsing, Filling & Capping set up with a production capacity ot 400 Jars per Hour..

Page 9 (1m 57s)

Fully Auto Blow & Semi Auto Blo (Back Up).

Page 10 (2m 5s)

BOPP, STICKER LABEL MACHINES & AUTO SHRINK MACHINE.

Page 11 (2m 12s)

Microbiology Lab. P!büiili dol d 01.

Page 12 (2m 19s)

Chemistry Lab. i'itJiiii.

Page 13 (2m 25s)

gmnnu— "iiüiiiiiiiiii. Office Room. Raw Material Storage Room.

Page 14 (2m 32s)

Finished Goods Storage Area Exit View.

Page 15 (2m 39s)

Generator Yard & Compressor Yard.

Page 16 (2m 46s)

Factory Backside View with Staff Rooms.

Page 17 (2m 53s)

*Oceana Step 7 : Mineralisation ( Added Minerals) Adding back the right amount of food grade minerals (Potassium + Magnesium) vital for human body which are lost in RO system. Improves quality & taste of product water. .00.

Page 18 (3m 53s)

Thank you.