Scene 1 (0s)

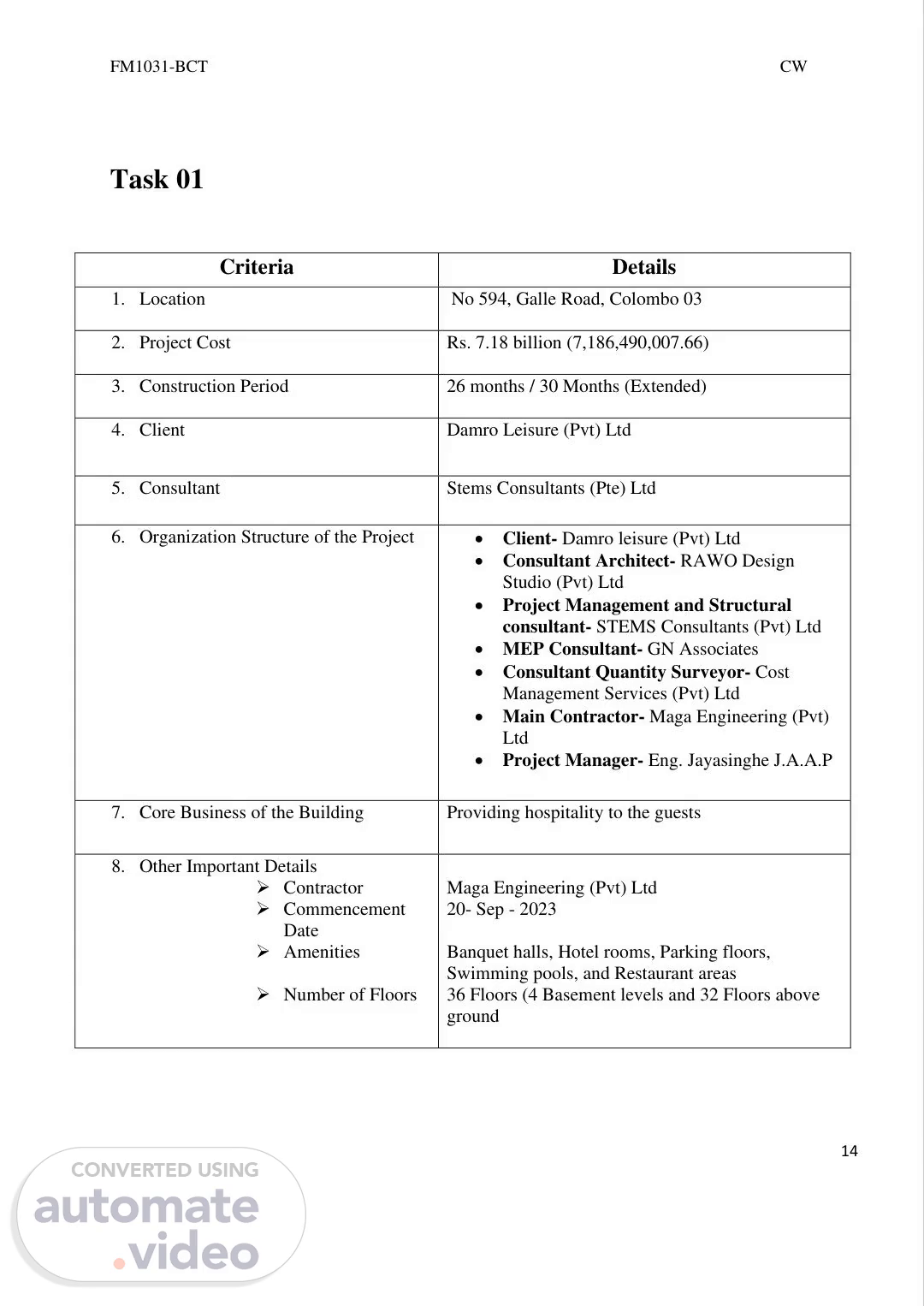

FM1031-BCT CW 14 Task 01 Criteria Details 1. Location No 594, Galle Road, Colombo 03 2. Project Cost Rs. 7.18 billion (7,186,490,007.66) 3. Construction Period 26 months / 30 Months (Extended) 4. Client Damro Leisure (Pvt) Ltd 5. Consultant Stems Consultants (Pte) Ltd 6. Organization Structure of the Project • Client- Damro leisure (Pvt) Ltd • Consultant Architect- RAWO Design Studio (Pvt) Ltd • Project Management and Structural consultant- STEMS Consultants (Pvt) Ltd • MEP Consultant- GN Associates • Consultant Quantity Surveyor- Cost Management Services (Pvt) Ltd • Main Contractor- Maga Engineering (Pvt) Ltd • Project Manager- Eng. Jayasinghe J.A.A.P 7. Core Business of the Building Providing hospitality to the guests 8. Other Important Details ➢ Contractor ➢ Commencement Date ➢ Amenities ➢ Number of Floors Maga Engineering (Pvt) Ltd 20- Sep - 2023 Banquet halls, Hotel rooms, Parking floors, Swimming pools, and Restaurant areas 36 Floors (4 Basement levels and 32 Floors above ground.

Scene 2 (43s)

[Audio] FM1031-BCT CW Task 2 Identify the basic structural types and describe the suitability for the proposed building During the field visit to the Damro Star class Hotel stage 3, we observed and studied the structural systems and construction processes used by Maga Engineering (Pvt) Ltd, one of the Sri Lanka leading contractors. The project includes the construction of high-rise hotel building with four basement levels and thirty-two upper floors, which requires highly advanced and durable structural solutions. The main structural systems used in this project are identified below. The hotel building mainly uses a reinforced concrete frame structure. This building has concrete columns, beams, slab, and walls, which form the efficient carriers of vertical and horizontal loads. The reinforced concrete system is suitable for multi-story buildings like hotels because its durability, flexibility in design, and high load bearing capacity. One of the main structural elements we identified was the transfer floors, this special floor helps redistribute the weight of the building from the upper floors to different arrangement on the lower levels. It commonly used in high rise building, especially when large open spaces like lobbies or banquet halls are require on lower floors. This is created with the concrete and heavy reinforcement, as well as the temporary supports until the floor has the capacity of supporting itself. The transfer floor offers architecture flexibility and effective control of the load management. Figure 2 Reinforcement cage Figure 1 Reinforcement cage The foundation style applied in this hotel is a deep foundation with cast in situ piles. This construction is required on heavy and tall buildings as it transfers load to the ground to help it be better supported. The piles are connected by pile caps which support the building weight. We were also able to observe the presence of diaphragm walls around the basement. These thick walls restrain the surrounding soil during the excavation process and, as well, keeps the basement from getting leaked by water. This is, in particular, relevant to underground structures. 15.

Scene 3 (2m 59s)

[Audio] FM1031-BCT CW Reinforcement work is a key part of construction.Steel bars of various sizes(from 8mm to 40mm)are used to strenghthen the concrete in foundations,slabs, columns, and walls.These bar are cut, and tied before pouring concrete. Different types of formworks, such as timber, plywood, and alumium systems, are used to hold the concrete untill it stiffen. Figure 3 Reinforcement The structure system adopted is quite appropriate to be used in luxury, high-rise hotel due to the following reasons High load Capacity: The building can carry a load of 32 floors with a basement reinforced concrete and pile foundations. The flexibility of the interior design : The inflexion of frame structures permits open quarters as restaurants and banquet halls with few columns inside. Durability : Durability is long term in relation to the resistance to environmental harm, which is offered by systems and concrete frame structures, and waterproofing techniques. Seismic Safety : The buildings of deep foundation and diaphram walls make the building more stable against ground disturbances and earthquakes. To sum up, the structural system employed in the damro star class hotel is perfectly suited to the type of modern high-rise building. This high strength and flexibility is fulfilled by reinforced concrete frame and stability and water protection are achieved by deep foundation and diagram walls. Transfer floors allow the large open spaces, and the quality and safety are ensured by the highly developed monitoring systems. The building is generally designed well in terms of durability and safety, as well as functionality. 16.

Scene 4 (4m 43s)

[Audio] FM1031-BCT CW Task 3 Identified Building Elements and Their Functional Requirements Foundation It is the base of all the building and hence it is called foundation. It plays an important role of transferring the weight of the structure to the underlying soil in a manner, which does not allow it to settle or move. Foundations can be of different types, and these include shallow foundations and deep foundations (as in the case of piles) depending on the nature of the building and site. Functions Safely transfers the loads inside the building to the ground Requirements The loads should be distributed to prevent settlement Give stable and level foundation Withstand ground movement and lateral push Avoid the effects of undermining and erosion Columns Columns are vertical structures that support loads that are placed overhead and move them to the base. They can be all sorts of shapes and sizes including rectangular, circular, or special shapes. The choice of the type and dimensions of a column is selected depending on architectural imaginations, the need of load and space stature of the building. Figure 4 Columns Functions Transfer of compressive loads of upper floors to the foundation Figure 5 Columns Requirements Capability of resistance to various forces Keep floors straightened up protection from environment factors Beams Beams are the horizontal members that are used to span between supports columns or walls and are used to take the load of the structure above. There exist beams of various shapes that include beams, beams, and box beams which all have a particular benefit in comparison to the load distribution and requirements of the construction. Functions Figure 6 Beams The support floor slabs and transfers the loads laterally Requirements Figure 7 Beams Stable enough to ensure that it does not bend and shear Keep buildings put up in place (have structural soundness) Fire-proof to guarantee safety 17.

Scene 5 (6m 39s)

[Audio] FM1031-BCT CW Slabs Slabs are horizontal surfaces that are used as floor and roof of a building. They may be rigid alone or braced with other materials such as steel or post tensioned cables to make them stronger. The kind of slab to be taken into consideration is based on factors like the span, the load bearing of the slab and the purpose the space will serve. Functions Provide usable horizontal surfaces Requirements Figure 8 Slabs Structural multi support live and dead loads Strengthen the building and fire safety Offer sound and heat insulation Floors A horizontal surface that forms the base of a room or story, providing a level area for walking and supporting the weight of the structure, its contents, and occupants. Functions Offer a walking surface and structural back up Requirements Durability Provide resistance to fire and sound proofing Strength and stability Figure 9 Floors Walls The superstructure of the main portion of this project is reinforced concrete walls. Significant walls such as shear walls, lift shaft, and staircase core assist in stability as well as movement of loads to the foundation. Columns, slabs, and walls are cast in combination to create a powerful structure. Blocks walls shall be constructed later in the project in areas such as toilets, service ducts and other partitions that consist of separating of areas and not just because of loads. Functions Provide support of vertical loads and lateral loads Requirements Structural strength Dimensional Accuracy Durability Fire Resistance 18.

Scene 6 (8m 15s)

[Audio] FM1031-BCT CW Staircases Concrete staircases linked multiple floors and were designed for safety and emergency use. Functions Support the movement of people in the vertical direction Requirements Heat resistant and structurally powerful Provide safe, easy movement Exit in case of emergency Figure 10 staircases 19.

Scene 7 (8m 38s)

[Audio] FM1031-BCT CW Task 4 Building materials used in the structural work Most of the structural materials, which were evident during the site visit of Damro Star Class Hotel project, were used to suit the requirements of a high-rise building that has 4 basements and 32 storeys. Such materials were identified as the strongest, resistant to long terms (durability), water resistance (backroom spaces), and loads. Concrete, reinforcement steel, and bentonite slurry, waterproofing products, and other support materials were the main materials that were employed. Concrete Structural components such as pile caps, raft slabs, columns, beams, walls, and floor slabs were mostly composed of concrete. Depending on the strength required, different mixes were applied. As an example, there was a higher level of concrete used in the transfer floor that is helpful in transferring loads where columns do not match. Temperature controls were applied during big pours, particularly that of the transfer floor, to avoid peeling and even curing. Figure 11 Concrete Reinforcement steel Another major construction material was the reinforcement steel. There were two kinds used: Tor steel (high-bond deformed bars) and mild steel (links and stirrups). Depending on the structural requirements, Tor steel of 8mm- 40mm, and 6mm mild steel was used as secondary reinforcement. Cutting, bending, and fixing of bars were done on site through machines and manual processes. The concreting resulted in use of various tying techniques including Slash, Hairpin, Crown, Rinn Slash, Ring Hairpin and Splice to hold the bars into position. Figure 12 Reinforcement steel Bentonite Slurry During piling and diaphragm wall building, deep stabilized excavations were done by use of bentonite slurry. It was prepared as a mixture of bentonite powder and water and transported in tanks to be pumped in the boreholes to avoid collapse during the drilling. Reinforcement cages were put in position and then concrete poured by the tremie method to obtain clean and uniform filling after excavation. Waterproofing Materials Water proofing was noteworthy since a lot of the construction was underground. In the interior, the waterproofing membrane was crystalline to seal cracks and in the exterior, the surface coatings and membranes were applied over bitumen primer. A drop of water resistance was achieved by mixing additives into concrete as well. All these techniques worked to manage the basement to be dry and free of ground water. 20.

Scene 8 (11m 15s)

[Audio] FM1031-BCT CW Formwork Systems Used Formwork takes the concrete and shapes it, supports it until it gets hard and is self-supporting. The formwork system predominantly used in the project is the Mivan formwork system which is a modular aluminium system that is lightweight, reusable and is best used in quick and precise casting of structural elements like columns, walls, and slabs. This system gives a good smooth surface finish and minimizes plastering and re-work Column Formwork Column formwork the main method of column formwork is Mivan aluminium panels which enable speedier, and precise work. Set and remove is harder because of its vertical location and close spacing. Columns are cast along with walls and beams which makes the process rather complex. Timber is used as timber formwork on special occasions such as lintels or irregular shapes that Mivan would not manage. Figure 13 Column Formwork Wall Formwork The Mivan system is also applied in wall formwork, and this gives a wall of uniform thickness and straight alignment. The Pecones and GI pipes are employed in tying panels together, and in withstanding the pressure of fresh concrete. Where the wall is irregular or where there is a need to have an aesthetic treatment, then form tiles or plywood with timber frames can be applied. Figure 14 Wall Formwork Slab formwork Figure 15 Wall Formwork Slab formwork is primarily performed through Mivan aluminium panels reinforced by scaffoldings and steel supports. Horizontality and free workspace make it easier to install and remove compared to column and beam formwork. Slab, beams, and walls are cast together in the system. Adjustment is made using plywood sheets in certain corners. The panels are stipulated by tie rods and Pecones, leaving round circles on the concrete that are then filled. Curing involves back propping to maintain stability of the slab till it gains strength. Figure 16 Slab Formwork 21.

Scene 9 (13m 14s)

[Audio] FM1031-BCT CW Beam Formwork Beam formwork which is the products of the Mivan system, is cast in conjunction with slabs and columns. They are more time-consuming to install and tear down as compared to slabs due to a heavier reinforcement and their connection with other parts of the structure. It is held in place using GI pipe bracing and timber is placed in case special shapes or openings are required. Figure 17 Beam Formwork Staircases Formwork Depending on the complexity of these designs, staircases are created through Mivan panels or through custom plywood with wood framing. The steps and landings are made carefully and with the scaffolding. Its proper bracing will provide accuracy in pouring the concrete, and reinforcement at a location must be set before the form setup. Transfer Floor Formwork The high loading and complex shape of transfer floor requires more formwork. It also employs Mivan panels, scaffolding, GI bracing as well as Pecones. It is quite challenging to construct formwork because it is very big and heavily reinforced. The casting is by stages and the cast is back propped during the curing phase to make it stable. 22.

Scene 10 (14m 29s)

[Audio] FM1031-BCT CW Task 5 Construction methods The construction has deep and shallow foundations. To retain soil, diaphragm walls are constructed to keep out water and maintain the structure stable during earthquakes when constructing deep foundations. This will include erection of the guides walls, trench excavation, making the steel reinforcement cages and pouring concrete. Bentonite mud is applied in the soil to support it during drilling in piling work. In conditions where deep foundations are not essential, shallow foundations, such as strip, pad, and raft foundations, will be applied. Dewatering pumps pump the groundwater out of the site, and the leaks in the basement are prevented by various waterproofing solutions (such as crystalline coating, cement coating, and bitumen primer). The project also has a transfer floor which assists in shifting the load of the top floors to other locations that are lower than others. This is necessary in construction, such as those with unenclosed areas, such as lobbies or banquet halls. To construct these floors, heavy reinforcement, good concrete, as well as back propping (temporary supports) have been used. Concrete is expected to be structured using formwork, which is either timber, plywood, or aluminium material. When the concrete is being dried, formwork is provided to keep it in place and contain it. The concrete pouring can be performed after cutting, bending, and tying bars of steel of different sizes (e.g., 8 mm to 40 mm). Safety Methods Every worker is required to use PPE (Personal Protective Equipment), which includes hats, gloves, boots, goggles, the high-vis jackets. Warning signs are also displayed within the site, particularly those that are around the risk sites. The scaffold is constructed safely, with guard rails and toe boards, and safety nets are put up to receive falling equipment or to cushion people. Dangerous areas are blocked with barrier tapes and fences, and several fire extinguishers are positioned. 23.

Scene 11 (16m 35s)

[Audio] FM1031-BCT CW Machineries and equipment The construction site of the Damro Star class hotel employs a great variety of machines and tools to assist in the acceleration of the work, making it safer, and more efficient. Tower cranes The Tower cranes are meant to collect heavy material such as beams of steel, concrete, and building machineries to the upper parts of the construction. In appearance this tower cranes are very tall and fixed to the ground, with long horizontal arm that rotates. Figure 19 Tower crane Figure 18 Tower crane Concrete pumps The concrete pumps are involved in transfer of concrete liquid in a mixer truck to the site of the construction. This concrete pump pumps the concrete in a pipeline or a hose too hard to reach locations that trucks cannot penetrate, especially at higher places or narrow sideways. Such concrete pump types include Boom pumps (which has an arms) and the line pumps (which has flexible hoses) Figure 20 Concrete pumps 24.

Scene 12 (17m 38s)

[Audio] FM1031-BCT CW Generators Generators are meant to give electricity in times where grid electricity is not available. On construction sites, these generators power up tools, lights, and machines. These generators can work on diesel, petrol, or gas. Figure 21 Generator Skid steer The purpose of skid steer loaders is to digging, lifting, and moving materials.This machines has compact with lift arms on each side, can have different attachements (buckets, drills, forks). Figure 22 Skid steer Construction hoists / passenger hoists Construction hoists are like elevators, which assist people and materials to reach another floor of the building. These construction hoists look like cages attached to scaffoldings or towers. They serve a very vital purpose in high-rise construction as they are used to carry loads with ease, and in a timely manner. Figure 23 Passenger hoists 25.

Scene 13 (18m 37s)

[Audio] FM1031-BCT CW Doosan Air compressor The purpose of these is to produce compressed air to tools like jackhammers, drills, and paint sprayers. "Doosan'' is a well-known manufacture of industrial equipment. This are very useful where electricity is not available or when high-power air tools are needed. Figure 24 Doosan air compressor Other key machines are the excavators used in digging a big hole or trenches, and the wheelbarrows or trolleys used in moving the materials over short distances. 26.

Scene 14 (19m 9s)

[Audio] FM1031-BCT CW Task 6 Sri Lanka National Building Code (SLNBC) Maga Group applied this code in several areas Architectural design Architectural work has been done in a way that is suitable for a hotel. Structural design Since the sea is close, the design is being done in a way that can withstand strong winds and waves. Fire-resistant safety systems Fire extinguishing systems included fire extinguishing equipment as well as fire suppression equipment on the roof. It was also seen that there was fire extinguishing equipment on each floor. Plumbing and drainage systems Authorities said that hot/cold water supply systems are expected to be implemented in this 35-story building. British Standards (BS) and Eurocodes (EC) Maga as a Tier-1 contractor often incorporates BS and EC in construction of high-rises Using high quality construction materials that meet British and European standards. Standards affecting construction - BS 8110 or EC2 (EN 1992) Standards affecting concrete - BS 5950 or EC3 (EN 1993) Standards affecting steel - BS 6399 or Eurocode 1 (EN 1991) Standards affecting electrical work - BS 7671: IEE Wiring Regulations Standards affecting electric lifts - EN 81 & BS 5655 used for hotel and mall The Urban Development Authority regulations The building is under construction at a coastal site according to the Urban Planning Regulations Fire and other hazards safety regulating rules. Hydrogen systems and equipment to extinguish or fight fire are utilized Both inside and outside the building to be used in case of fire and emergency. e.g.: -SLNBC Part III -Sri Lanka Fire Department Guidelines 27.

Scene 15 (21m 7s)

[Audio] FM1031-BCT CW Evaluation of the minimization of environmental impacts Proper systems for waste management and programs for environmentally friendly activities should be implemented. Standards of Tourism Development Authority Since this is being built for a 5-star hotel, the following services and facilities must be met. Health Safety Protocols Minimum room facilities and proper sanitation required to be a 5-star hotel Construction Industry Development Authority Regulations The construction activities should be conducted according to the proper registration of constitution activities and the safety of occupational acts in construction activities. 28.

Scene 16 (21m 51s)

[Audio] FM1031-BCT CW Conclusions and Recommendation Damro Star Class Hotel Stage 3 is a high-rise complex in Colombo 03, Sri Lanka, that is constructed to provide a modern luxury hotel with guest's comfort and structural strength. This site visit report is written on the actual visit made on 7th June 2025, where several important points, such as structural features, materials, safety, and management of the site, were noted down. Students gained practical information during their visit, and it made the preparation of classroom theory to link with the actual construction. It also demonstrated the necessity of an effective coordination, qualified labourers, contemporary techniques such as a Mivan formwork as well as sound consideration of safety and sustainability in a big project. Apply green strategies Use environment friendly materials and minimize wastage. Improve safety Ensure everyone who works in the field wears the required safety clothes and puts safety regulations to prevent accidents. Control costs Continue monitoring the budget and expenditure to prevent money wastage during construction. Employ talented employees Properly trained workers can work better and faster with less mistakes. Quality should be good Obtain the right materials and examine the job that is made to make certain that it is rough, and well built. 29.

Scene 17 (23m 15s)

[Audio] FM1031-BCT CW References Damro Leisure (Pvt) Ltd. (2025). Proposed Star Class Hotel Stage 3 project – Site briefing and construction details. Colombo, Sri Lanka. Maga Engineering (Pvt) Ltd. (2025, June 7). Site visit discussion and verbal explanations by site engineers and project manager. Maga Engineering (Pvt) Ltd. Sri Lanka | Govalkar, U. B., & Rao, R. (2024). Structural and non-structural components. In Habitats: Holistic Approaches to Building, Interiors and Technical Systems (Chapter 4). Notion Press. https://doi.org/10.52458/9788196897444.nsp2024.eb.ch-04 CivilSeek. (n.d.). Formwork for concrete – Its types, materials, & requirements. CivilSeek. https://civilseek.com/formwork-for-concrete/ 30.

Scene 18 (24m 7s)

[Audio] FM1031-BCT CW Annexes Figure 25 Figure 26 31 Figure 27 Figure 28.

Scene 19 (24m 22s)

[Audio] FM1031-BCT CW Figure 31 Figure 32 Figure 29 Figure 30 32.

Scene 20 (24m 38s)

[Audio] FM1031-BCT CW Individual Contribution Student Name Contribution Knowledge Gained Kajana V Task 1 & Task 4 Learned about project details, roles, team structure and mainly about materials and mivan formwork use. Hanshani T.M.U Task 2 Understood substructure work like pilling and waterproofing. Soysa T.I.U Task 3 Gained knowledge of columns, slabs, beams, and wall. Viduranga H.S.N Task 5 Understood the building technologies, machinery and equipment used for the construction Jayarathna M.H.A.N Task 6 Understood site testing, quality control methods, and building code applications used to ensure safety and compliance in construction. 33.