Page 1 (0s)

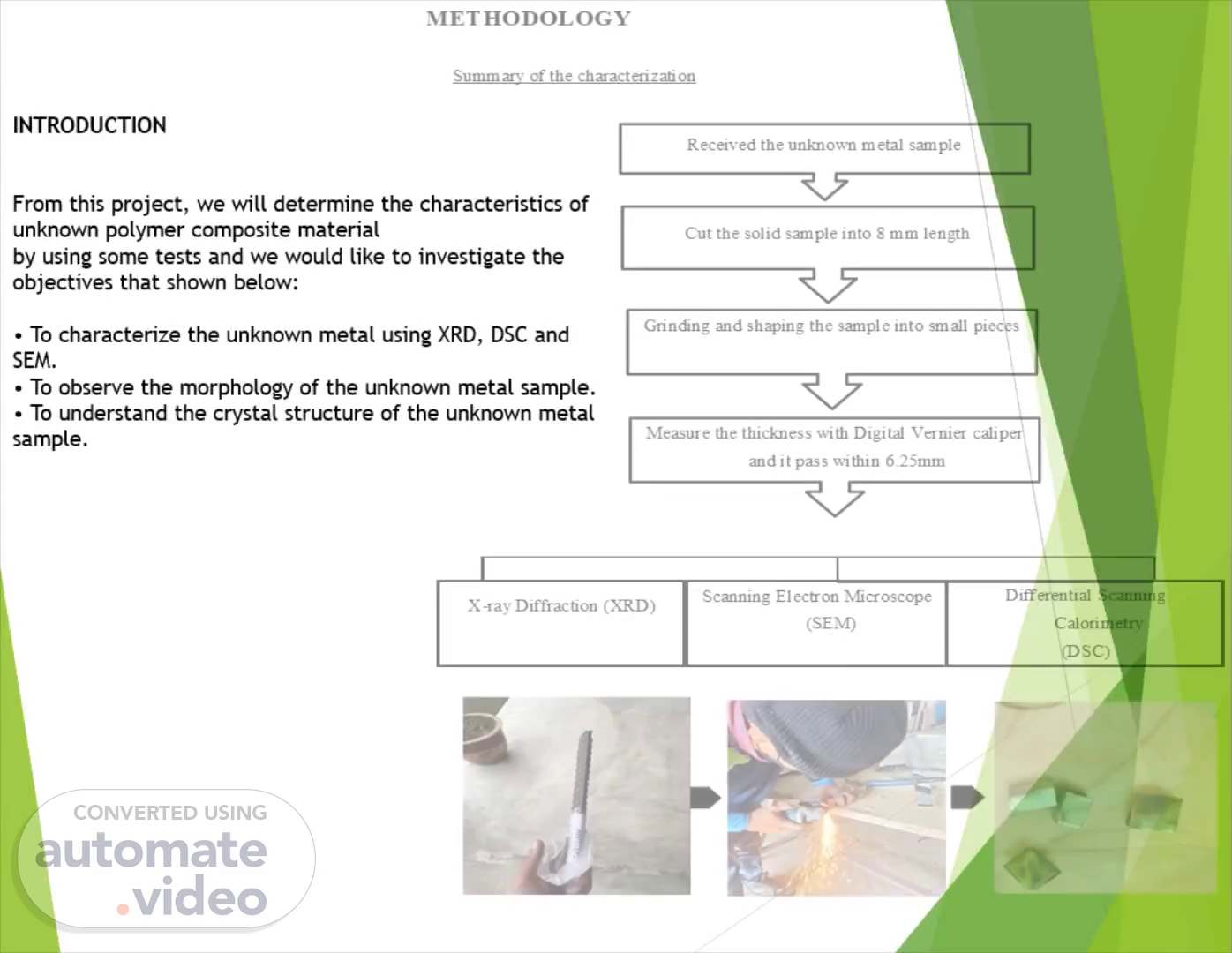

abstract. INTRODUCTION From this project, we will determine the characteristics of unknown polymer composite material by using some tests and we would like to investigate the objectives that shown below : • To characterize the unknown metal using XRD, DSC and SEM. • To observe the morphology of the unknown metal sample. • To understand the crystal structure of the unknown metal sample..

Page 2 (25s)

X-ray Diffraction (XRD) Result & Discussion The figure below displays the XRD results for the sample. Figure 1: Result of xrd sample compound that were selected. Figure 2: Unknown metal bulk sample parameter pattern list.

Page 3 (39s)

Figure 3: Chromium search & match score Following XRD results, X'Pert HighScore Plus is used to analyze crystallographic data and estimate phase in an unknown sample. After identifying the context, the peak is searched, followed by a search match and modification. As seen in Figure 1, unknown metal bulk sample components. Chromium, Kamacite,Aluminium Copper, and Aluminum Beryllium Copper are the four most likely components to be found an unknown metal sample. Figure 3 shows that chromium is the most prevalent element in the sample with the highest score, 78. The highest peak intensity was found in the XRD diffractograms of this samples, which 44.371 2Ɵ respectively. The lattice characteristics of the component phases are almost similar in all composites. Composites' compositions may change, but their structure stays constant..

Page 4 (1m 28s)

(a) 1440 Tuo 1 Exo rscx 1470 1510. Temperatures of peritectic transition (solidus temperatures) were found during heating experiments. It was observed that the heating rate slightly affects this temperature. In case of steel 1, for both heating rates, T PER = 1,485 ± 1 °C, and for steel 2, it was approx. T PER = 1,489 °C . 2) The strongest dependency on heating rate was observed for liquidus temperature. For the heating rate of 5 °C min−1, the obtained results are more reliable because of the smallest overheating of the samples. Liquidus temperature in case of steel 1 was T LIQ = 1,537 ± 3 °C, and in case of steel 2 T LIQ = 1,524 ± 3 °C . 3 ) During cooling experiments, the peritectic transition temperature was shifted to lower values due to the supercooling of the sample. In case of steel samples, overheating is much smaller than overcooling. Thus, more reliable results are obtained during heating experiments 4) Owing to small enthalpy changes during austenite transformation into δ-ferrite, the DSC method has limitations, and the temperature of the transformation is hardly measurable. 5) The obtained values of temperatures of phase transitions are in good agreement with those calculations conducted for equilibrium state . DSC curves of steel 2 obtained during heating ( a ) and cooling ( b ) with the heating/cooling rates of 5 and 20 °C min −1 ; characteristic temperatures: T γ→δ temperature of δ - ferrite.

Page 5 (2m 22s)

lekv xsee Sػrn 12 38 SEI. SEM Surface review and cross-section Figure 1 Surface review of bulk sample T16 steel bar at magnification of x500 . Figure 2 Cross section of bulk sample T16 steel bar at magnification of x1,000 . As we can see, there are signs of polish and grinding at the sample surface. Rough surfaces can exhibit light and dark zones according to local changes in the surface orientation. The quantitative analysis of surface topography include measuring microstruc tural feature sizes and their distribution/density, quantifying the 3D morphology of objects, measuring particles (size, number, and shape), examining porosity (size, distribution, and tortuosity), cracks (size, shape, length, and interconnection), and quantifying failure sites such as fracture surfaces and tribological wear surfaces were observed SEM application.

Page 6 (2m 57s)

CO NCLUSION Three different methods were used to analyse the unknown metal sample in solid form, including XRD, DSC, and SEM. XRD analysis distinguishes the compound composition, revealing that the unknown metal sample solid form contains three components with the highest percentages, such as Aluminum Beryllium Copper, Aluminium Copper, and Chromium. In the unknown sample, the major component is chromium, which is found at 81.693 2Th.. DSC was used to analyse the thermal properties of an unknown metal solid form, which revealed an endothermic heat flow event. The effect of the 10°C/min heating rate does not highlight the peak; a higher heating rate > 10°C/min should be used. The computer system estimated the latent heat of melting (fusion) to be around 251.4 J/g (by integrating the DSC curve within the boundaries we specified). The microstructure of an unknown metal sample form revealed that the particle texture is stoned shape solid sharp edge. At x500 magnification, it shows porous morphology. This unknown metal appears to have porosity, though only in a few places. This sample has a stoned size solid particle and a weak fine surface with a variety of particle sizes and shapes, as well as multiple porosities in one region or area. Due to magnificent limitations, the grain boundary and grain growth development cannot be seen or dis cussed..