Scene 1 (0s)

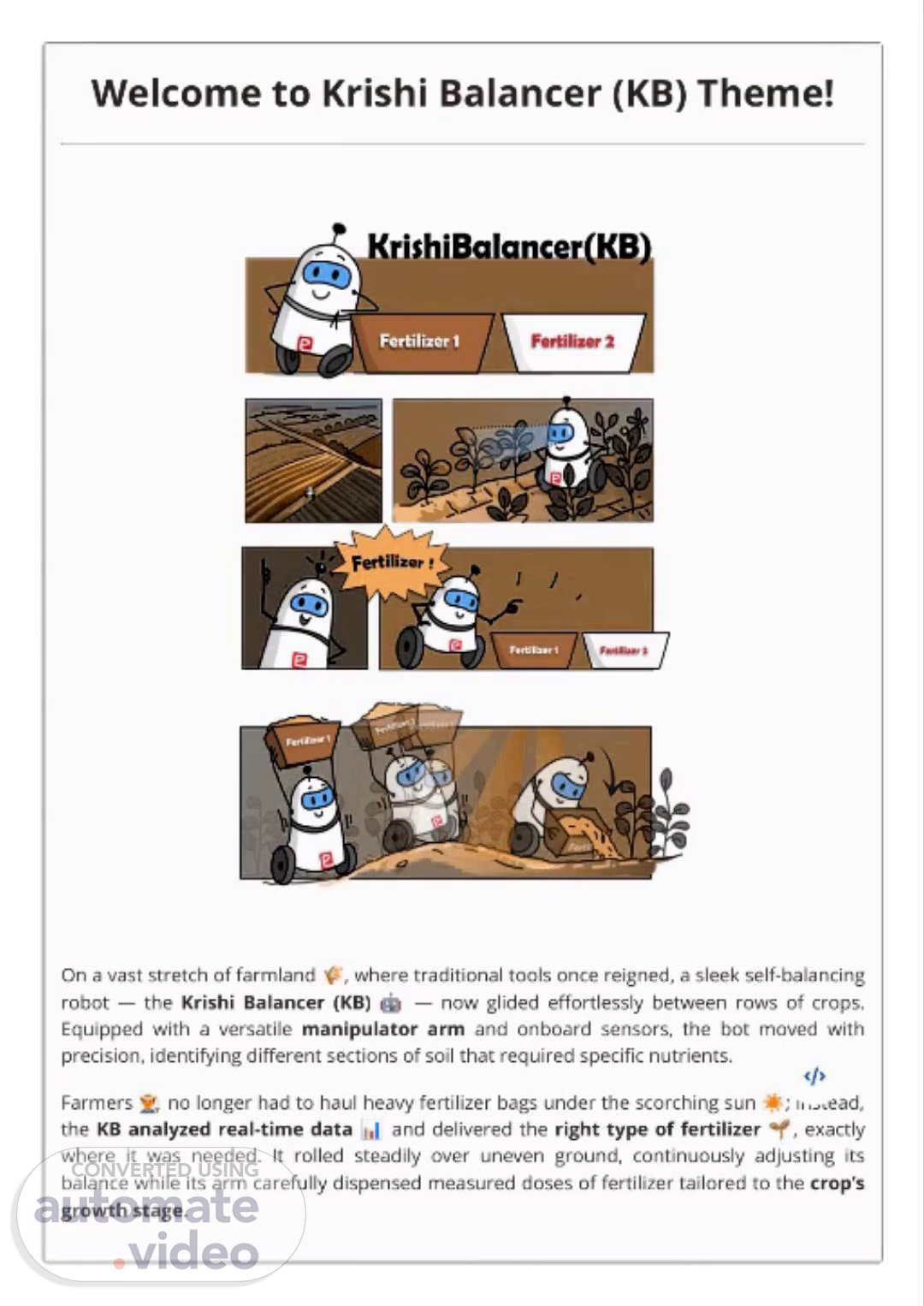

Welcome to Krishi Balancer (KB) Theme! On a vast stretch of farmland 🌾, where traditional tools once reigned, a sleek self-balancing robot — the Krishi Balancer (KB) 🤖 — now glided effortlessly between rows of crops. Equipped with a versatile manipulator arm and onboard sensors, the bot moved with precision, identifying different sections of soil that required specific nutrients. Farmers no longer had to haul heavy fertilizer bags under the scorching sun ☀; instead, the KB analyzed real-time data 📊 and delivered the right type of fertilizer 🌱, exactly where it was needed. It rolled steadily over uneven ground, continuously adjusting its balance while its arm carefully dispensed measured doses of fertilizer tailored to the crop’s growth stage..

Scene 2 (2m 2s)

[Audio] This is slide number 2 of our 50-slide presentation, where we will be discussing the Krishi Balancer (KB). This self-balancing robot has revolutionized farming by making it more intelligent and efficient. With the use of sensors and a manipulator arm, the KB is able to gather real-time data and dispense the perfect amount of fertilizer for each crop. This results in a reduction of manual labor, waste, and an overall improvement in crop yields. Powered by sensor data and PID-based control, the KB represents a shift from traditional farming to smart and sustainable agriculture. It is a symbol of the advancements in technology that have brought a new level of efficiency and productivity to the farming industry. More than just an engineering marvel, the KB is a quiet revolution making its way through the farming world, one plot at a time. Its presence in the field is a game-changer, leading us towards a more sustainable future in agriculture. As we continue with our presentation, we hope to inspire you with the endless possibilities that the Krishi Balancer offers. So let's keep building and learning, as the journey of innovation starts here. We wish you great success as we journey towards revolutionizing the agricultural landscape..

Scene 3 (3m 21s)

[Audio] Today, we will be showcasing the Krishi Balancer, a self-balancing robot designed to bring efficiency and sustainability to farming. We will be discussing the capabilities of KB and how it can revolutionize the agricultural industry. This includes its ability to glide between rows of crops, collect real-time data, and automatically dispense the appropriate amount of fertilizer for each crop. One of the main advantages of KB is its ability to take on labor-intensive tasks, freeing up time and energy for farmers. Additionally, KB helps keep track of tasks and deadlines, ensuring a more streamlined farming process. With KB, farmers can increase productivity and contribute to a more sustainable future. Thank you for your attention and stay tuned for more exciting information on KB and its impact on the agricultural industry..

Scene 4 (4m 16s)

[Audio] This slide will discuss the resources that will help you understand the control system of the Krishi Balancer, a self-balancing robot designed for farmers. We will cover the overall concept of control system, its importance in the functioning of the KB, its components and sensors, and how they ensure the smooth operation of the robot. We will also explore modelling and analysis of systems, which is crucial in understanding the KB's behavior and response to different conditions and inputs. This knowledge will not only be useful in the upcoming quiz, but also in effectively utilizing the KB in the field. We will also discuss the modeling of a simple pendulum, a fundamental example that will aid in understanding the KB's control system. Additionally, we will look into Lagrangian mechanics, which plays a significant role in the control system design of the KB. Finally, we will touch upon two popular controllers, the LQR controller and PID controller, which are essential for maintaining the stability and accuracy of the KB while navigating through rows of crops. By the end of this slide, you will have a solid understanding of the control system, which will be useful in the quiz and in improving your agricultural practices with the KB. Let's move on to the next slide to learn more about the Krishi Balancer..

Scene 5 (5m 38s)

[Audio] Slide number five of our presentation is focused on the Krishi Balancer (KB) - a revolutionary self-balancing robot that is changing farming practices. This slide will cover the control system of the KB and the fundamental concepts that make it highly effective. A control system is a collection of devices that work together to perform a specific task. In the case of the KB, the control system manages the input and output of the system for optimal functioning. It is made up of two main components - the controller and the actuator. The controller acts as the brain, processing sensor input and generating control output to the plant or system. On the other hand, the actuator is responsible for controlled movement or output based on the control output from the controller. There are two main types of control systems - open loop and closed loop. Open loop systems do not have a feedback element, while closed loop systems have a feedback element and are more complex. The KB is a closed loop system, equipped with sensors for real-time data and a manipulator arm to distribute the appropriate amount of fertilizer to crops. This not only saves farmers from manual labor, but also ensures precise and efficient use of resources for optimal crop growth. Thank you for joining us on this journey to learn more about the Krishi Balancer and its remarkable control system. Stay tuned for more exciting information in the upcoming slides..

Scene 6 (7m 11s)

[Audio] In this slide, we will be discussing the concept of a closed-loop system and its application to our self-balancing robot, the Krishi Balancer (KB). A closed-loop system uses feedback to continuously monitor and adjust its output. For the KB, this means that the robot will receive real-time data from its sensors and use it to make precise adjustments to maintain balance and accurately dispense fertilizer. The video below explains the inner workings of a real control system and its crucial role in the design process of the KB. Throughout the design process, the control system plays a vital role in ensuring the success of our self-balancing robot. As we progress through this presentation, remember the significance of a closed-loop system and how it contributes to the efficiency and effectiveness of the KB..

Scene 7 (8m 5s)

[Audio] In this presentation, we will be discussing the Lagrangian mechanics and modeling of the Simple Pendulum. This is a crucial aspect to understand in order to fully comprehend the functionality of our Krishi Balancer (KB) self-balancing robot. It is important to have a strong foundation in classical mechanics and a good grasp of mathematical concepts such as partial differentiation, Jacobians, and solving equations with multiple variables. These are key topics that will be helpful in understanding our presentation. Our main topic is the Euler-Lagrange method, which is used to calculate the equations of motion for a system. This method plays a vital role in understanding the dynamics of our KB robot and how it operates. By utilizing the Euler-Lagrange method, we can obtain the accurate equations of motion for our self-balancing robot, enabling precise movements. Let's now delve into the details of this method and how it is crucial for the proper functioning of our KB robot. More on this will be discussed in the upcoming slides..

Scene 8 (9m 11s)

[Audio] Slide number 8 of our presentation on the Krishi Balancer (KB) will be discussing the concept of the Lagrangian and its role in the operation of the self-balancing robot. The KB is equipped with sensors and a manipulator arm and is designed to glide between rows of crops on farmland. It relieves farmers from the manual labor of fertilizing their crops by dispensing the right type and amount of fertilizer based on real-time data. The Lagrangian is a crucial concept in understanding the motion of the KB. It represents the energy of the system at any given moment and is calculated using the state variables of position and velocity in a generalized coordinate system. To better understand this concept, let's look at an example of a point mass being raised to a height of y. By calculating the Kinetic and Potential Energies and then determining the Lagrangian, we can use the Euler-Lagrange method to analyze and make adjustments to the KB's motion for smooth operation. The Lagrangian is a crucial element in the functioning of the KB, allowing us to understand and control its movements and make it a valuable tool for farmers in maintaining their crops. We will now move on to slide number 9 to discuss the dynamics of the KB..

Scene 9 (10m 31s)

[Audio] This slide focuses on the Krishi Balancer, a self-balancing robot designed for use on farmlands. This advanced robot is equipped with sensors and a manipulator arm that allows it to dispense the perfect amount and type of fertilizer based on real-time data. This not only eliminates the labor-intensive task of manually fertilizing crops but also ensures that each crop receives the precise amount of nutrients it needs. Three equations are presented on this slide - (1), (2), and (3). Equation (1) demonstrates that potential energy is stored in a mass when it is raised to a certain height. Moving on to equation (2), which may seem complex at first, we know that the kinetic energy of a point mass can be calculated using (1/2) x mass x (velocity)^2. Since velocity (v) is the rate of change of height (y) with respect to time (t), we can rewrite the equation as (1/2) x mass x (dy/dt)^2. The third equation (3) shows the Lagrangian (L), which is the difference between the kinetic and potential energy of the system. To determine the equations of motion, we use the Euler-Lagrange method. Finally, equation (6) gives us the answer to our question - the system's acceleration (y¨) with gravity (g) as the only force acting on it. This is logical, since the only force acting on the system is gravity. If we had used Newton's laws of motion, the result would have been the same, but the approach would have been different. Let's take a look at a more complex example in the next slide. Exciting information about the Krishi Balancer will be shared in the following slides..

Scene 10 (12m 30s)

[Audio] We will be discussing how our Krishi Balancer, a self-balancing robot designed to aid farmers, works on slide number 10. This machine uses sensors and a manipulator arm to dispense fertilizer while navigating through uneven farmland. To understand its balance, we will use the pendulum equation and Euler-Lagrangian method. The system consists of a pendulum with a bob attached to a rigid rod. We will determine the Lagrangian and calculate the kinetic and potential energy of the pendulum. Our Krishi Balancer uses this concept to glide through fields and make farmers' lives easier. We will also discuss the types and amounts of fertilizer it can dispense, based on real-time data. Stay tuned for more insights as we continue with our presentation..

Scene 11 (13m 21s)

[Audio] Slide 11 of our presentation discusses the Krishi Balancer (KB), a self-balancing robot designed to assist farmers with their daily tasks. Equipped with advanced sensors and a manipulator arm, this robot can glide between crop rows and dispense the appropriate amount of fertilizer using real-time data. This not only eliminates manual labor for farmers, but also promotes optimal crop growth and yield. We will be focusing on the mathematical concepts involved in the motion of our KB robot on this slide. The moment of inertia (I) and angular velocity (ω) are crucial factors in determining the motion of any rotating object, including our robot. ω can be expressed as the rate of change of θ with respect to time (dθ/dt). This information allows us to calculate the kinetic energy of our system, as well as the potential energy. By combining these, we can determine the Lagrangian (L) and use it to determine the equations of motion for our KB robot. θ and ω have been selected as the state variables for our system, allowing for easy calculation of the equations of motion using the Euler-Lagrange method. This approach has been successful in deriving the equations for our KB robot, further confirming the accuracy of our methods. With a deeper understanding of the mathematical principles behind the motion of our KB robot, we can now move onto the next slide to explore the real-life applications of this revolutionary technology..

Scene 12 (14m 59s)

[Audio] In slide number 12, we will discuss the Krishi Balancer (KB), a self-balancing robot created to assist farmers in their tasks. The KB is equipped with sensors and a manipulator arm to navigate through rows of crops and dispense the appropriate amount of fertilizer based on real-time data. It uses equations to maintain balance and stability while in motion. External forces can also affect the KB's movement, so it is crucial to consider and account for them in its design. This is just one aspect of the many factors that were taken into consideration during the development of the KB. Please join us for slide number 13 to learn more about the unique capabilities of the KB..

Scene 13 (15m 48s)

[Audio] Slide number thirteen of our presentation focuses on the Krishi Balancer (KB) and its dynamics as a self-balancing robot in agriculture. The KB is equipped with sensors and a manipulator arm that uses real-time data to accurately distribute fertilizers, streamlining the farming process for our farmers. However, when a non-conservative force is present, the system's chosen states of angular position and velocity must also account for the presence of an angular force or torque. This is evident in the Euler-Lagrange equation, where external forces are included on the right side. For a more specific example, in the pendulum system, the equations of motion will have an additional term. By examining the dimensions of angular acceleration (alpha in rad/s2) and torque (T^-2), it is clear that the torque is equal to the moment of inertia multiplied by angular acceleration, which is determined by the mass and length of the pendulum. This confirms the presence of an angular acceleration term in the equation. Dimensional analysis is a useful tool in verifying the accuracy of our equations. In summary, the Krishi Balancer (KB) is a valuable tool in agriculture that can handle non-conservative forces. As we continue our presentation, we will delve deeper into the technical aspects of this innovative robot. Thank you for your attention and feel free to ask any questions during the Q&A session..

Scene 14 (17m 24s)

Happy brainstorming guys!!.

Scene 15 (17m 30s)

[Audio] This slide focuses on the stability of our Krishi Balancer, a self-balancing robot designed to improve farming efficiency. The main challenge in dealing with non-linear dynamical systems is determining if they are stable or unstable. To understand this, we must first define an equilibrium point, which is when the system does not change. By setting x˙ 1 and x˙ 2 to 0 and solving the equations, we can find the equilibrium points of our system. These points can be either stable, meaning the system will return to them after small perturbations, or unstable, meaning the system will move away from them. The equations provided on this slide show the equilibrium points of (0,0), (-1,1), and (1,-1). To further analyze the stability of our system, we must linearize the equations by calculating the Jacobian. This allows us to create a linear approximation of the non-linear system. In conclusion, the stability of our Krishi Balancer is crucial for its successful operation in gliding between rows of crops on farmland. By accurately determining the stability, we can ensure that the robot is equipped with the appropriate sensors and manipulator arm to dispense the correct amount and type of fertilizer based on real-time data. Please stay tuned for the next slide, where we will delve deeper into the inner workings of the Krishi Balancer..

Scene 16 (19m 4s)

[Audio] Slide number 16 covers the process of linearizing equations for our self-balancing robot, the Krishi Balancer, designed for farmlands. To achieve this, we must first calculate the Jacobian, which is a matrix used to linearize equations. The Jacobian is found by taking partial derivatives of the equations with respect to each variable. Once obtained, we then substitute the equilibrium points in the matrix to find three different matrices - J₁, J₂, and J₃. The next step is to calculate the eigenvalues of each matrix, which represent the poles of the system. These poles play a crucial role in determining the stability of our system. If the poles are on the negative half of the complex plane, the system is considered to be stable. However, if the real part is positive, the system is unstable. A system is also marginally stable if it has simple poles on the imaginary axis and unstable if the poles are repeated. We can apply this to our Krishi Balancer by comparing it to a simple pendulum. When the pendulum is in a downward position, it is stable, but when it is in an upright position, it is unstable. To verify the stability of our system, we must find the Jacobian around the two equilibrium points and analyze the eigenvalues. This can be done by constructing the characteristic equation of the matrix and equating it to zero. This will give us the eigenvalues for the equilibrium point (0,0). In summary, to linearize equations for the Krishi Balancer, we calculate the Jacobian, substitute equilibrium points, and analyze eigenvalues. This process determines the stability of our self-balancing robot, ensuring its successful operation on farmlands..

Scene 17 (20m 58s)

[Audio] Our presentation will now dive into slide 17, focusing on the Krishi Balancer (KB) and the stability of its system at various equilibrium points. The KB is a self-balancing robot designed for use on farmland, using real-time data to dispense fertilizer accurately while navigating through crop rows. To determine the stability at equilibrium points (-1,1) and (1,-1), we must analyze the real part of the calculated eigenvalues. A system is considered stable if all eigenvalues have a negative real part, while even one positive real part signifies instability. Moving on to the eigenvalues for equilibrium point (0,0), both (-1-i) and (-1+i) have negative real parts, confirming stability at this point. However, at equilibrium points (1,-1) and (-1,1), the eigenvalues (2+2√2) and (2-2√2) respectively reveal an unstable system. In conclusion, stability at different equilibrium points is crucial for the KB to effectively dispense the correct type and amount of fertilizer, alleviating farmers from manual labor. There is more to come in our presentation; thank you for listening..

Scene 18 (22m 26s)

[Audio] Slide number 18 of our presentation focuses on the Krishi Balancer, a self-balancing robot revolutionizing farming. Here, we will discuss the modelling and analysis of systems using state space representation. In control engineering, a state-space representation is a mathematical model that uses input, output, and state variables connected by first-order differential or difference equations to describe a physical system. The state variables are dynamic and change over time, based on their current values and received inputs. The output variables are dependent on the state variables, meaning their values directly impact the output. For the Krishi Balancer, the state space equations for a linear time-invariant system can be defined as the state vector, denoted as x(t), and the output vector, denoted as y(t). These equations are crucial in understanding and optimizing the performance of the robot as it navigates through farmlands and dispenses fertilizer based on real-time data. By using this state space representation, we can model and analyze the behavior of the Krishi Balancer, allowing us to make necessary adjustments and improvements to its design and function. This is just one of the many factors that make the KB an efficient tool for farmers, reducing manual labor and increasing productivity. In the next slide, we will delve deeper into the technical aspects of the Krishi Balancer and how it is transforming agriculture. We hope you continue to learn and be inspired by the potential of our invention..

Scene 19 (24m 6s)

[Audio] During our journey to explore the capabilities and potential of the Krishi Balancer (KB), we have reached slide number 19. This slide discusses the mathematical equations used in the functioning of the KB. The matrices highlighted on this slide, such as the Input Vector, State Matrix, Input Matrix, Output Matrix, and Feed-Forward Matrix, are crucial in the operations of the KB. However, we will not delve into the theory and complex math behind these equations in this presentation. For more in-depth information, reliable Control Systems books are recommended. Now, let's focus on the equations shown on the screen, specifically in the form of equation (2). However, you may have noticed the Bu term missing. This is because our system does not have any input and only relies on state variables x₁ and x₂. This raises the question - can we express the set of equations (1) in terms of (2)? The answer is no, as (1) contains non-linear equations while (2) contains linear equations. However, if we linearize (1), it is possible to express (1) in terms of (2). To do this, we must first find the equilibrium points, as discussed in the previous task. These points play a crucial role in determining the stability of the system. To find the equilibrium points, we must set the derivatives ẋ₁ and ẋ₂ to 0 and solve the resulting equations for x₁ and x₂. This process gives us the equilibrium points of (0,0), (1,√2), and (1,-√2). Finally, we need to calculate the jacobian of the system of equations, which will provide us with a better understanding of the behavior and functioning of the KB. This slide has provided a brief overview of the mathematical aspect of the KB, and our journey continues with more exciting information about this revolutionary self-balancing robot..

Scene 20 (26m 17s)

[Audio] We will now discuss the jacobian J for the system of equations (3). This jacobian is an important tool in our development of the Krishi Balancer (KB), a self-balancing robot designed for farmland use. The KB is equipped with sensors and a manipulator arm for gliding between rows of crops and dispensing the right type and amount of fertilizer based on real-time data, relieving farmers from manual labor. To achieve precision and efficiency, we must first calculate the jacobian's value for each equilibrium point. This will help us understand the system's behavior and make accurate adjustments. Next, we will look at the state equation for each equilibrium point. For example, the state equation for equilibrium point (0,0) will be formulated as [Formula for state equation for equilibrium point (0,0)]. It is important to note that our equations are expressed in the form of (3), but this approximation is only valid for points near the equilibrium point (0,0). The jacobian J and state equations are essential components in the development of the KB, allowing us to create a self-balancing robot that balances the needs of crops and farmers' labor. Let's move on to the next slide..

Scene 21 (27m 37s)

[Audio] Slide number 21 of our presentation is focused on the Krishi Balancer (KB), a self-balancing robot designed specifically for farmlands. This innovative technology utilizes real-time data to move between rows of crops and accurately dispense the appropriate amount and type of fertilizer, reducing the need for manual labor. What sets the KB apart is its impressive stability. Our research has shown that the non-linear system behaves like a linear system near the equilibrium point of (0,0), ensuring stability and control for optimal results. However, the system is not stable at all equilibrium points. For points (1,√2) and (1,-√2), the system is unstable due to positive real values in the eigenvalues of the A matrix. To address this, we have implemented a control input, using a similar linearization technique as before. Our goal is to determine the equilibrium points for the Pendulum with external applied torque system. Through calculations, we have found that there are two equilibrium points for the physical description of a pendulum: (0,0) when the bob is vertically downwards, and (π,0) when the bob is vertically upwards. In summary, the KB is a remarkable technology that not only eases the burden of manual labor for farmers, but also maintains stability and control for more efficient and precise fertilizer application. This concludes slide number 21 of our presentation..

Scene 22 (29m 21s)

[Audio] Slide number 22 of our presentation on the Krishi Balancer (KB) will discuss the stability and operation of our self-balancing robot on farmland. It is assumed that the system will be stable at the equilibrium point (0,0) and unstable at the equilibrium point (π,0) due to the sensors and manipulator arm that allow it to dispense the appropriate amount of fertilizer based on real-time data. This relieves farmers from manual labor, increasing their efficiency and yield. The jacobian of the system of equations, J₁ for the A matrix and J₂ for the B matrix, will be calculated. Substituting the values of (x₁, x₂) in the jacobian for each equilibrium point will help us understand the stability of our system. The A matrix values for each equilibrium point are (A matrix values for each equilibrium point). This analysis confirms that the KB is a highly stable and efficient self-balancing robot that can glide between rows of crops and provide the right amount of fertilizer, while reducing manual labor for farmers. More insights will be presented in the upcoming slide..

Scene 23 (30m 39s)

[Audio] Slide number 23 of our presentation focuses on the revolutionary Krishi Balancer (KB), a self-balancing robot designed to optimize farming and reduce labor. With advanced sensors and a manipulator arm, the KB can glide through crop rows, using real-time data to dispense the appropriate amount and type of fertilizer. This perfect balance is achieved through understanding the state equations at each equilibrium point. An equilibrium point is a state where all forces and torques are balanced. The B matrix, which represents the necessary values for equilibrium, plays a crucial role in the KB's function. To determine the B matrix for each equilibrium point, we use linearization, a mathematical method to construct the state equation. For the first equilibrium point at (0,0), the state equation is [insert equation]. And for the second equilibrium point at (π,0), the state equation is [insert equation]. These equations allow us to comprehend the KB's behavior at various equilibrium points and aid in maintaining its balance. However, just having equilibrium points is not enough for stability. We must also check the system's stability by examining the eigenvalues at each point. At equilibrium point (0,0), the eigenvalues [insert values] indicate a stable system. Similarly, at equilibrium point (π,0), the eigenvalues [insert values] also demonstrate a stable system. In conclusion, the Krishi Balancer is not only a self-balancing robot, but also a highly stable and efficient one, thanks to its complex system of equilibrium points and state equations. This unique feature sets it apart from traditional farming methods and makes it a game-changer in the agricultural industry. We will now proceed to slide number 24.".

Scene 24 (32m 43s)

[Audio] This slide focuses on the stability of the Krishi Balancer (KB) and how it is affected by eigenvalues. The eigenvalues for the coordinates (0,0) are purely imaginary, indicating marginal stability, with the system continuing to oscillate indefinitely. However, for the coordinates (π,0), the eigenvalues are purely real with a positive real part, making the system unstable. It is important to note that for a system to be stable, its eigenvalues should lie within the unit circle. Moving on, we will discuss two crucial properties of the system - controllability and observability. Controllability is the system's ability to drive a state from any initial value to a final value in a finite amount of time by providing a suitable input, determined by the controllability matrix. Observability, on the other hand, allows us to determine the current state of the system in finite time using only the outputs, determined by the observability matrix. A fully observable system means we can obtain information about all the state variables from the system outputs. The controllability and observability matrices can be calculated using the formulas shown on the slide. In summary, the KB is not only efficient and time-saving, but it is also designed with a stable and controllable system, ensuring maximum productivity and ease of use for farmers. Let's move on to the next slide to learn more about this groundbreaking technology..

Scene 25 (34m 19s)

[Audio] As we are now on slide number 25, we will be discussing the controllability and observability of our Krishi Balancer (KB) - the self-balancing robot designed to revolutionize farming. The term "fully controllable" means that we have complete control over the system's behavior and can manipulate it as desired. Similarly, a fully observable system allows for accurate perception and measurement of its current state. In the case of our KB, the number of state variables (represented by n) refers to various factors that affect the robot's movement and performance, such as soil quality, humidity levels, and environmental conditions. The rank of a matrix is the maximum number of linearly independent rows or columns in that matrix, representing the number of unique equations that can be derived from the matrix. In our KB, the A and B matrices provide the necessary information to calculate controllability. By looking at our example of a pendulum with an external torque, we can determine the controllability of our KB. The rank of the R matrix is 2, equal to the number of state variables, indicating that our KB is fully controllable and can be manipulated as desired. For further understanding, we have provided additional resources on controllability and observability, as well as a conceptual approach to these concepts. We have also included resources on state and state variables, and an introduction to state-space equations. For those interested in the application of controllability, we have included information on pole placement and full state feedback. With this technical understanding, we are confident that our self-balancing robot has the capability to revolutionize farming and relieve farmers from manual labor. Let's now move on to the next slide..

Scene 26 (36m 17s)

[Audio] The Krishi Balancer (KB) is a revolutionary self-balancing robot designed for the farming industry. Slide number 26 provides a closer look at this invention and its potential impact on agriculture. Equipped with advanced sensors and a manipulator arm, the KB can navigate between rows of crops and dispense the perfect amount of fertilizer based on real-time data, optimizing crop growth and yield. Manual labor for farmers is now a thing of the past as the KB takes care of all the work. It is a game-changer in the farming world, offering cutting-edge technology and precise fertilizer dispensing. Inspired by a legend who believed in the power of technology to better the world, the KB represents our constant strive for progress and development. Let us embrace this creation and move on to the next slide to discover more about its capabilities..

Scene 27 (37m 13s)

[Audio] In slide number 27, we will focus on the topic of LQR controller. State space analysis is a useful tool for understanding and controlling dynamic systems. In our presentation today, we will delve into the different types of controller design. Let's start by considering the State Space Equations of a system, which provide a powerful understanding of a system's behavior in terms of its state variables. By analyzing these equations, we can make necessary adjustments to achieve our desired results. Next, we will discuss the LQR controller, which is a popular control technique that optimizes system performance by minimizing a cost function. This robust and effective controller takes into account the system dynamics, desired performance specifications, and control effort. Finally, we will show how the LQR controller can be applied to the Krishi Balancer (KB), our self-balancing robot designed to assist farmers in their manual labor. The KB is equipped with sensors and a manipulator arm to dispense the right type and amount of fertilizer based on real-time data, making farming more efficient and less labor-intensive. By incorporating the LQR controller, the KB can accurately and efficiently navigate through rows of crops, providing the perfect amount of fertilizer for each plant. This not only relieves farmers from manual labor but also ensures optimal growth and yield for their crops. Now, we can move on to further exploring the capabilities of the KB. Thank you for your attention and we look forward to your participation in the discussions..

Scene 28 (38m 57s)

[Audio] Slide number 28 of our presentation focuses on the Krishi Balancer (KB), a revolutionary self-balancing robot designed for farmers. With the growing demand for sustainable and efficient agriculture, the KB is here to revolutionize farming. Equipped with sensors and a manipulator arm, this robot glides between rows of crops on farmland, collecting real-time data and dispensing the ideal amount and type of fertilizer. This eliminates the need for manual labor and allows farmers to focus on other important tasks, increasing overall productivity. But how does the KB achieve such precision? The use of reference points, gains, and state and output vectors are key factors in its success. The reference point, denoted as r, serves as a crucial point of comparison for the KB. The gain, denoted as Kr, is the value used to multiply the reference point to achieve the desired output. The state vector, denoted as x, represents the current state of the system and is multiplied by the reference point to determine the output vector, represented as y. The input to the system, denoted as u, is multiplied by the gain, denoted as K, to achieve the desired output. In simpler terms, the KB utilizes advanced technologies to continuously monitor and adjust its actions based on real-time data, ensuring precise and optimal dispensing of fertilizer for each crop. This eliminates the risk of over or under-fertilizing, resulting in healthier crops and higher yields. The KB is truly a game-changer for the agricultural industry and we are excited to see the positive impact it will have. Stay tuned for more information on the Krishi Balancer, including a closer look at the different types of sensors used in this innovative robot on slide number 29..

Scene 29 (40m 56s)

[Audio] We are currently on slide number 29 out of 50, where we will be discussing the Krishi Balancer - a revolutionary self-balancing robot designed to assist with crop cultivation. This robot is equipped with sensors and a manipulator arm to dispense the correct amount and type of fertilizer in real-time, making it easier for farmers. Let's now focus on the system behind this remarkable technology. The Krishi Balancer relies on a gain matrix, which is used as feedback to maintain a stable balance while moving between crop rows. The State Equation for the system is written in the form of a new state matrix (A-BK), which defines the dynamics of the system. By inputting -Kx, we can assess the system's stability by calculating the eigenvalues of the (A-BK) matrix. This provides us with more control over the system and guarantees its stability. One approach to controlling the system is through the use of a Linear Quadratic Regulator (LQR). This enables us to place the eigenvalues anywhere in the left half plane, as long as the system is controllable. This is a critical aspect in ensuring the successful operation of the Krishi Balancer. We hope you now have a better understanding of the technical aspects of this innovative technology. Our next step is to move on to the next slide..

Scene 30 (42m 21s)

[Audio] In this section, we will be discussing slide number 30 out of 50 of our presentation on the Krishi Balancer (KB). We have previously covered the robot's self-balancing capabilities, use of sensors and a manipulator arm for dispensing fertilizer on farmland, and the importance of stability. However, now we must consider where to place our eigenvalues in the system. Our focus shifts to the desired outcome and how to use optimization and the gain matrix K to achieve it. The Linear Quadratic Regulator and its use of a cost function and positive semi-definite diagonal matrices will assist us in choosing the appropriate K matrix. It is important to note that for a diagonal matrix, the diagonal entries are its eigenvalues. The state vector x and input vector u are also crucial components in this process. We will use a system with four states and one input, specifically x1, x2, u, and input, to better understand this concept. By optimizing our K matrix, we can successfully achieve the desired response from our system. The Linear Quadratic Regulator will aid in this process, making it efficient and effective. Stay tuned for more insightful information in the remaining slides..

Scene 31 (43m 42s)

[Audio] We will be discussing the controller system and cost function of the Krishi Balancer (KB) on slide 31 out of 50. The KB is a self-balancing robot that dispenses fertilizer using real-time data, eliminating manual labor for farmers. The controller uses a Linear controller, u = -Kx, and Quadratic cost function, making it a Linear Quadratic Regulator. The weights for each state, represented by Qi, play a crucial role in achieving the desired performance. For a single input system, we can choose R = 1, and for multiple inputs, we can use similar arguments to weigh them. In our case, the inverted pendulum, the angle and angular velocity are key factors for achieving balance, so it is essential to carefully select the weights for these states in the cost function. This allows the KB to glide between rows of crops and effectively dispense the right amount of fertilizer, making the lives of farmers easier. Let's move on to the next slide..

Scene 32 (44m 46s)

[Audio] This slide will discuss the math behind the optimal control system of the Krishi Balancer (KB). The KB is a self-balancing robot designed for use in the agriculture industry. Its sensors and manipulator arm allow for precise and efficient dispensing of fertilizer based on real-time data. The control system utilizes a Linear Quadratic Regulator (LQR) algorithm to optimize the robot's movements for the best performance. To find the optimal matrix K, we use the Algebraic Riccati Equation (ARE) and an inbuilt LQR command in Octave. For those interested, we recommend learning more about LQR and the importance of the Riccati Equation in this context for a deeper understanding of the KB's efficient control system. Let us appreciate the advanced technology behind the KB and its potential impact on the agriculture industry. Now, let's move on to our next slide..

Scene 33 (45m 51s)

Happy learning!!!!.

Scene 34 (45m 56s)

[Audio] In this slide, we will discuss the PID controller, which is a key component of our self-balancing robot. The PID controller is a type of feedback control system used in industrial processes. It uses a mathematical algorithm to regulate and maintain a desired set point. This controller takes input from sensors on the robot and calculates the error between the desired set point and the current state. It then adjusts the manipulator arm to dispense the correct amount of fertilizer in real-time. This precise process ensures optimal nutrient distribution for crops, reducing the manual burden on farmers and preventing over or under-fertilization. The PID controller is essential for the success of our Krishi Balancer, making it an efficient and sustainable solution for modern agriculture. Stay tuned for our next slide where we will explore the benefits of the Krishi Balancer in more detail..

Scene 35 (46m 53s)

[Audio] Slide number 35 of our presentation focuses on The Krishi Balancer (KB), our self-balancing robot designed to assist farmers with their crop fertilization process. Today, we will be discussing the role of control engineering, specifically the importance of the PID controller. PID controllers play a critical role in maintaining stability and efficiency in complex systems across various industries, such as automotive, aerospace, manufacturing, and robotics. Understanding PID controllers will give us a better understanding of key concepts like feedback, stability, and dynamic response, which are essential for optimizing the performance of our KB robot. The knowledge of PID controllers is crucial as it allows our KB robot, equipped with sensors and a manipulator arm, to analyze real-time data and accurately dispense the correct type and amount of fertilizer to crops. This not only reduces manual labor for farmers but also ensures the most efficient use of resources. As we near the end of our presentation, I encourage you to continue exploring the world of control engineering and its numerous possibilities. Thank you, and let's now move on to slide number 36..

Scene 36 (48m 15s)

[Audio] Slide number 36 of our presentation focuses on the Krishi Balancer (KB) - a self-balancing robot designed for use in agriculture. This technology is equipped with sensors and a manipulator arm, allowing it to efficiently dispense fertilizer based on real-time data while seamlessly maneuvering between crop rows. By eliminating the need for manual labor, the KB robot brings a new level of efficiency to farming. The term PID stands for Proportional Integral Derivative and is commonly used in industrial settings to precisely control various process variables. The PID controller of the KB robot utilizes a combination of actions to constantly monitor and adjust its movements, making it a reliable and effective tool for farmers. The use of the KB robot frees farmers from physically demanding manual labor and allows them to focus on other important aspects of their farm. With its advanced technology and PID controller, the KB robot improves the efficiency and precision of agriculture, making it a valuable addition to any farm. In conclusion, the KB robot is a game-changing technology in the world of farming. It streamlines the fertilization process, improving crop production and the overall health of farmlands. Stay tuned for more developments on the Krishi Balancer..

Scene 37 (49m 38s)

[Audio] Slide number 37 of our presentation focuses on the Krishi Balancer (KB), a self-balancing robot designed for efficient farming. The control loop feedback device is an essential element in the KB's operations, as it regulates all process variables. This type of control is crucial in driving the KB system towards its objective location or level, and is commonly used in temperature control, scientific processes, automation, and chemical applications. Its main purpose is to maintain the real output of the system close to the desired objective or fixed point. In this article, we will explore the PID controller design, which uses three control modes (P, I, and D) to ensure the stability and accuracy of the KB system. These control modes work together to dispense the right type and amount of fertilizer based on real-time data. The P mode adjusts control variables based on the difference between the desired and actual outputs, while the I mode considers accumulated error over time to bring the output closer to the desired level. The D mode anticipates changes in process variables and adjusts the control input accordingly. This combination of control modes results in a highly efficient and precise system that relieves farmers from manual labor. Through closed-loop feedback, the KB is able to achieve optimal performance and revolutionize the world of farming. In conclusion, the control loop feedback device is a crucial component in the KB's functioning, ensuring that the system always works towards its objective with utmost accuracy. By using the PID controller design and its control modes, the KB brings efficiency to farming. Stay tuned for more insights on the KB..

Scene 38 (51m 28s)

[Audio] In this slide, we will be discussing the PID Controller Block Diagram. A PID controller is a closed-loop system that utilizes a feedback control system. One of the benefits of the PID controller is its ability to provide more accurate results compared to the ON/OFF type controller. By using this advanced feedback control system, the Krishi Balancer is able to accurately dispense the right type and amount of fertilizer onto farmland, relieving farmers from the manual labor of doing so. This not only saves time and effort, but also leads to more efficient and effective farming practices. Please continue to the next slide for more information on this impressive technology.".

Scene 39 (52m 15s)

[Audio] Our presentation is about the Krishi Balancer (KB), a self-balancing robot that helps farmers with their daily tasks. Slide number 39 out of 50 will focus on the KB's controller system. The KB has a advanced controller that operates based on two conditions. When the process value drops below a certain point, the KB turns ON, and when it goes above another point, it turns OFF. This ensures precise control of the KB's operations. However, this type of controller does have limitations as the output can be unstable and fluctuate around the fixed point. Nevertheless, it is still a more reliable and accurate option compared to the traditional ON/OFF controller. With the KB's controller, farmers can be confident that their crops are receiving the right amount of fertilizer based on real-time data. This not only saves them from manual labor but also ensures the health and productivity of their crops. Thank you for your attention and please continue to the remaining slides as we explore the amazing capabilities of the Krishi Balancer..

Scene 40 (53m 24s)

[Audio] Slide number 40 introduces the Krishi Balancer (KB), a self-balancing robot designed for use in farmland. Equipped with advanced sensors and a manipulator arm, the KB glides effortlessly between rows of crops and dispenses the correct type and amount of fertilizer based on real-time data. The key components of the KB's functioning include the system setpoint, error signal, control signal, and system output. The system setpoint, or r(t), is the desired optimal value that the KB aims to achieve. The error signal, or e(t), helps the robot fine-tune its actions to accurately meet the setpoint. The control signal, or u(t), enables the KB to make necessary adjustments in real-time based on the error signal. The system output, or y(t), is the final result of the KB's actions. This precise and efficient functioning of these parameters makes the KB a game-changer for farmers, as it eliminates the need for manual fertilizing. This not only saves time, effort, and resources for farmers but also ensures the optimal use of fertilizers for a healthy crop yield. With this, we conclude our discussion on slide number 40, and we hope you now have a better understanding of the KB's key components and potential impact in the field of agriculture. Let's move on to our next slide..

Scene 41 (54m 57s)

[Audio] Slide 41 focuses on the Krishi Balancer's PID controller and the mathematical calculations involved. The KB is a self-balancing robot that assists farmers with fertilization. It uses sensors and a manipulator arm to accurately distribute fertilizer based on real-time data. The PID controller is a crucial sub-controller in the overall operation of the Krishi Balancer. Its main function is to maintain the balance of the robot and ensure precise delivery of fertilizer. This requires complex mathematical calculations. The proper mathematical relation for the PID controller includes all the functions of its sub-controllers to ensure efficient operation and optimal results. At time t, the control output is represented by u(t) and the error, defined as e(t), is equal to the desired output (r(t)) minus the actual output (y(t)). This is multiplied by the proportional gain, kp, allowing the controller to adjust fertilizer output in response to the error and maintain balance. While these calculations may seem complex, they are crucial in making the KB an effective tool for farmers. With the use of the PID controller, the KB can move smoothly between rows of crops and dispense the right amount of fertilizer, reducing manual labor for farmers. With a better understanding of the mathematical calculations behind the KB's PID controller, we hope you can see its significance. Thank you for your attention and stay tuned for the remainder of the presentation..

Scene 42 (56m 36s)

[Audio] Today we will be discussing the Krishi Balancer (KB), a self-balancing robot designed for the agriculture industry. The robot has sensors and a manipulator arm, allowing it to navigate between crops and distribute the correct amount of fertilizer based on real-time data. The precision and efficiency of the robot are achieved through the three components of the PID control system - Proportional, Integral, and Derivative. These components work together to measure the error, consider past errors, and measure the rate of change of error to maintain precise control. This advanced technology of the KB helps relieve farmers from manual labor and increases productivity. We are now on slide number 42 out of 50 and have covered the basics of the PID control system and its role in the KB's functioning. Let's continue to the remaining slides to learn more about this revolutionary robot.".

Scene 43 (57m 39s)

[Audio] Slide number 43 discusses the two control mechanisms of the Krishi Balancer (KB) self-balancing robot. The KB is equipped with sensors and a manipulator arm, allowing it to dispense the appropriate amount of fertilizer based on real-time data. This eliminates the need for manual labor and results in more precise fertilization of crops. Let's now focus on the technical aspects of the KB's control systems. The first mechanism is Proportional control, which responds to output once per time period to correct minor errors and maintain stability. The second mechanism is Integral control, which sums up past error values and uses them to calculate the final control value. If Proportional control fails to eliminate errors, Integral control takes over to eliminate accumulated errors from the past. Together, these control systems ensure efficiency, accuracy, and reliability in the fertilization process. Thank you for your attention and let's move on to the next slide..

Scene 44 (58m 45s)

[Audio] Slide number 44 of our presentation on the Krishi Balancer (KB) will discuss the importance of proportional, integral, and derivative actions in the KB's control system. Proportional action acts as a corrective measure to reduce errors, resulting in smoother and more stable movements. Integral action compensates for proportional action by regulating it with a memory of previous changes. Derivative action estimates future error values and enables rapid corrective action for larger changes and slower corrective action for slower changes. This action plays a crucial role in enhancing the KB's overall control and predicting and correcting potential errors. With all three elements working together, the KB achieves optimal performance and frees farmers from manual labor. Let's move on to our next slide..

Scene 45 (59m 46s)

[Audio] Slide 45 out of 50 showcases the performance of our Krishi Balancer (KB) in relation to setpoint conditions. The KB is a self-balancing robot designed to work on farmland and seamlessly maneuver between crops. Equipped with sensors and a manipulator arm, it can accurately dispense the right amount and type of fertilizer based on real-time data. This feature eliminates the need for manual labor and provides convenience for farmers. The KB's outstanding performance can be credited to its ability to act as the rate of change of the controller output. This allows it to quickly adapt to changing conditions and provide optimum nutrients for crop growth. For those looking to learn more about the KB and its functions, we recommend exploring additional resources to gain a deeper understanding of its capabilities. These resources also provide practical examples of PID controllers and information on how to tune them. Thank you for your attention on slide 45. Let's now move on to the next slide and continue exploring the wonders of the Krishi Balancer. Stay tuned!.

Scene 46 (1h 0m 53s)

[Audio] Stage 1 of the Krishi Balancer Theme focuses on the use of the Krishi Balancer (KB) in agriculture. Farming is a labor-intensive and time-consuming process, and manually spreading fertilizers can be both exhausting and damaging to crop yield and quality. The KB is a revolutionary self-balancing robot designed to ease this burden on farmers. By using sensors and a manipulator arm, it accurately dispenses the right type and amount of fertilizer based on real-time data, saving farmers time and energy while ensuring each crop receives the necessary nutrients for a higher yield and better quality produce. This stage consists of three simulator-based tasks: Task_0, which introduces the basics of the KB and its functions; Task_1, where participants control and simulate the KB's movement between crop rows; and Task_2, testing skills in accurately dispensing different types and amounts of fertilizer using the KB. No hardware is required, making this a more accessible and hands-on learning experience. The KB not only simplifies farming but promotes sustainability by efficiently using resources. Our project has the potential to greatly benefit farmers and the environment. We are excited to share our progress with you in this presentation. Let's dive into Stage 1 of the Krishi Balancer Theme..

Scene 47 (1h 2m 21s)

[Audio] We are now on slide number 47 where we will be discussing Task 0, an essential component of our project, the Krishi Balancer. This task is divided into two parts: Software Installation and a Quiz based on provided resources. Let's dive into the details of these tasks. The first part, Software Installation, is crucial in getting the Krishi Balancer up and running. It involves the installation of necessary software on the robot to ensure its proper functioning. This is vital for the success of the project as it is highly dependent on the correct software installation. Once the installation is complete, we will move on to the Quiz. This quiz is designed to test your understanding of the resources provided and will cover important information about the Krishi Balancer and its role in the farming industry. Be sure to pay close attention to the resources and prepare for the quiz. We wish you all the best and hope you have thoroughly prepared. This is an excellent opportunity to showcase your understanding of the Krishi Balancer and its functions. With that, we have now completed slide number 47 and will move on to the next one as we approach the end of our presentation. Thank you.

Scene 48 (1h 3m 41s)

[Audio] We will now continue our journey to explore the Krishi Balancer, or KB for short. This slide will focus on Task 0A, which is a crucial aspect of this self-balancing robot. The KB is designed to glide smoothly between rows of crops on farmland, making it a highly efficient and time-saving tool for farmers. What sets it apart is its use of sensors and a manipulator arm. The sensors allow the KB to collect real-time data about the crops and soil, giving it a better understanding of the specific needs of each area. This enables it to accurately dispense the right type and amount of fertilizer, ensuring that the crops receive the perfect balance of nutrients. This not only saves farmers from the labor-intensive task of manually fertilizing their crops, but also leads to higher yields and better quality produce. Let us take a moment to appreciate the efficiency and precision of the KB, making farming a more manageable and sustainable process. In the next section, we will discuss another important aspect of this innovative robot, so stay tuned..

Scene 49 (1h 4m 52s)

[Audio] In this presentation, we will discuss the Krishi Balancer (KB), a self-balancing robot that improves efficiency and accuracy in farming. Our focus will be on Task 0A, which involves software installation and testing. The KB has advanced sensors and a manipulator arm that can analyze real-time data and accurately dispense fertilizer to crops. The installation and testing of the software that drives the KB is a crucial step in the development process. The software enables the KB to make informed decisions based on the data it collects. Proper installation and precise setup is essential for the overall functionality and performance of the KB. Testing is also crucial in identifying potential issues and ensuring the KB operates flawlessly in the field. The combination of proper software installation and thorough testing is vital for the success of the KB and its impact on revolutionizing the farming industry. We are one step closer to providing a solution for farmers who struggle with manual labor. Our final slide will wrap up the presentation and discuss the future of this groundbreaking technology. Thank you for your attention.".

Scene 50 (1h 6m 11s)

[Audio] Our final slide will discuss the software installation for the Krishi Balancer (KB). As we all know, the KB is a self-balancing robot that assists farmers in managing their crops. It comes with sensors and a manipulator arm that dispenses the right amount and type of fertilizer according to real-time data, eliminating the need for manual labor. To fully utilize the KB's capabilities, software installation is necessary. This is a simple process that can be completed by following specific instructions for your operating system. Windows users can refer to the step-by-step guide, while Mac users can download the software and follow the prompts for installation. Linux users can find detailed instructions on our website. With the software installed and running on your device, you can remotely monitor and control the movements and fertilizer dispensing of the KB, greatly improving efficiency and accuracy in crop management. In conclusion, not only is the KB a revolutionary technology in the agricultural industry but it also offers a user-friendly software installation process. We would like to thank everyone for joining us in this presentation. We hope you found it informative, and we look forward to seeing the positive impact of the KB in the farming community. Thank you..