Scene 1 (0s)

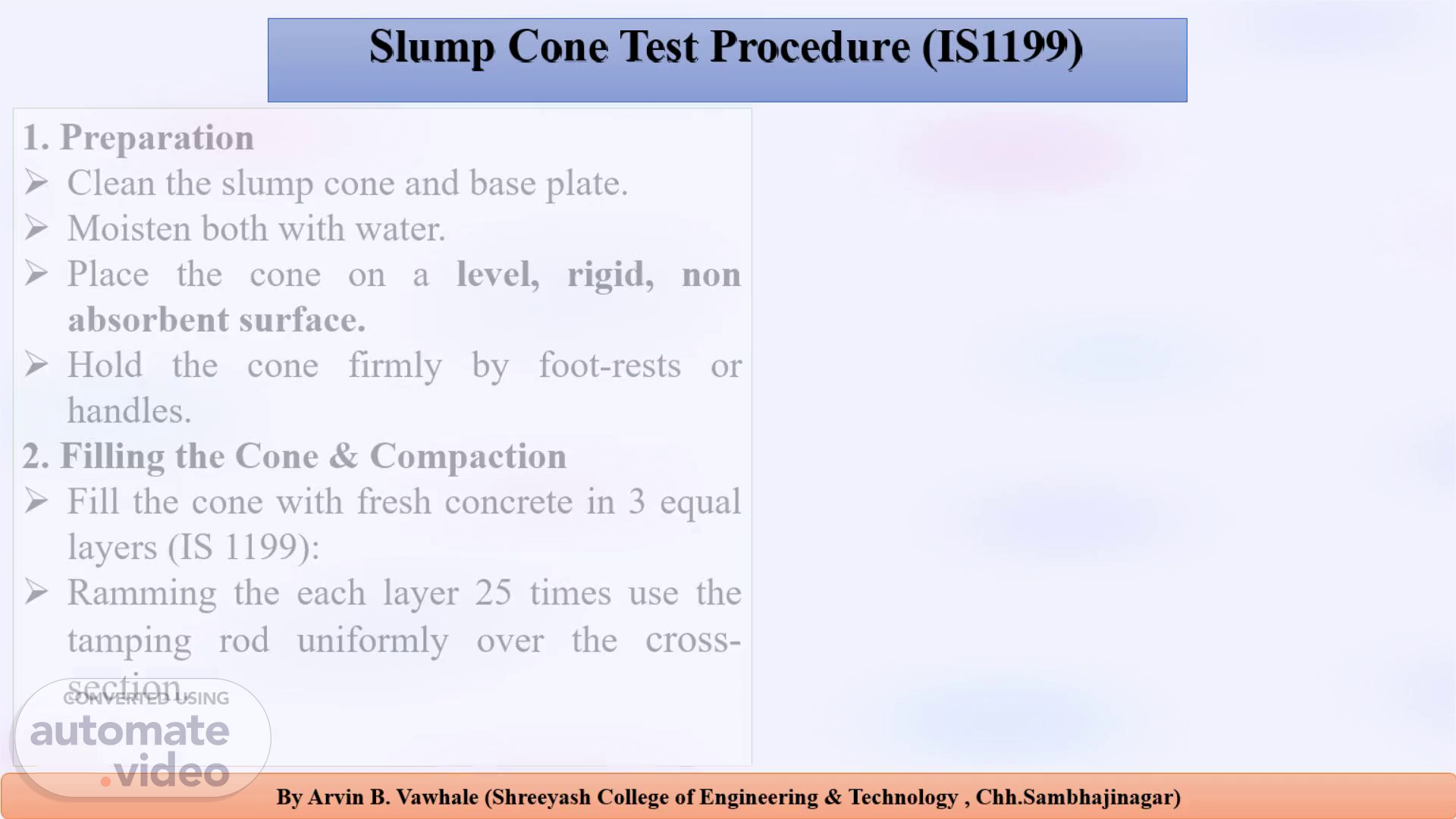

[Audio] Greetings of the day , In this video we are going to discuss and perform the Slump Cone Test Procedure as per Indian Standard 1199 And cube casting of concrete Greetings of the day , In this video we are going to discuss perform the Slump Cone Test Procedure as per Indian Standard 1199 And cube casting of concrete 1. Preparation Clean the slump cone and base plate. Moisten both with water. Place the cone on a level, rigid, non absorbent surface. Hold the cone firmly by foot-rests or handles. 2. Filling the Cone & Compaction Fill the cone with fresh concrete in 3 equal layers (Indian Standard 1199): Ramming the each layer 25 times use the tamping rod uniformly over the cross-section. 3. Striking Off & Lifting the Cone After the top layer, strike off excess concrete and make the surface level with the top of the cone. Lift the cone vertically upward. Time of lifting: 5 to10 seconds. Do not twist or tilt the cone. 4. Measuring the Slump Place the empty slump cone beside the slumped concrete. Measure the vertical difference between Top of cone & Highest point of slumped concrete..

Scene 2 (1m 26s)

[Audio] The above image shows the types of Slump as per Indian Standard 1199 -Based on Behavior of Concrete After Removing Cone: True Slump means Concrete subsides evenly, maintaining shape. Shear Slump means Concrete shears off laterally, indicating poor cohesion. Collapse Slump means Concrete collapses completely, indicating very high workability. Zero slump- indicate no workability.

Scene 3 (1m 56s)

[Audio] Step-by-Step Procedure for Cube Casting Sampling of Concrete (IS 1199) Take fresh concrete from mixer or transit mixer. Ensure sample is representative. Filling Moulds Clean and oil moulds lightly and fill in 3 layers for 150 mm cubes. Hand Compaction: Each layer tamped with 35 strokes uniformly. Vibration: Fill and vibrate till air bubbles cease. Finishing Level top surface with trowel and Cover with plastic sheet to prevent evaporation. Curing (Initial) Store moulds in moist air (relative humidity >90%) for 24±1 hours at 27±2°C. g (IS 516).

Scene 4 (2m 45s)

[Audio] Demoulding After 24 hours, mark cubes with identification. Remove carefully without damaging edges. Water Curing (IS 516) Immerse cubes in clean fresh water at 27±2°C until testing age and Change water every 7 days. 7. Testing Ages Usually 7 days and 28 days (as per IS 456). Additional tests at 3, 14, or 91 days if required. Compression Test Remove cube from water, wipe surface dry. Place in CTM with cast faces (not trowelled) in contact with platens. Align cube centrally. Apply load continuously at 5.2 N/mm²/min (approx 140 kN/min for 150 mm cube). Record maximum failure load..