Scene 1 (0s)

[Virtual Presenter] Our virtual event seminar series brings together innovators from around the world to share their expertise and showcase cutting-edge technologies that are transforming industries. The current session focuses on digital twin technology and its potential applications across multiple sectors. This technology enables companies to create virtual replicas of physical assets, allowing them to simulate and analyze complex systems, optimize performance, and reduce costs. By exploring the benefits and challenges of digital twin technology, we can gain valuable insights into how it can be harnessed to drive innovation and growth in various industries..

Scene 2 (44s)

Several safety instructions on a website AI-generated content may be incorrect..

Scene 3 (52s)

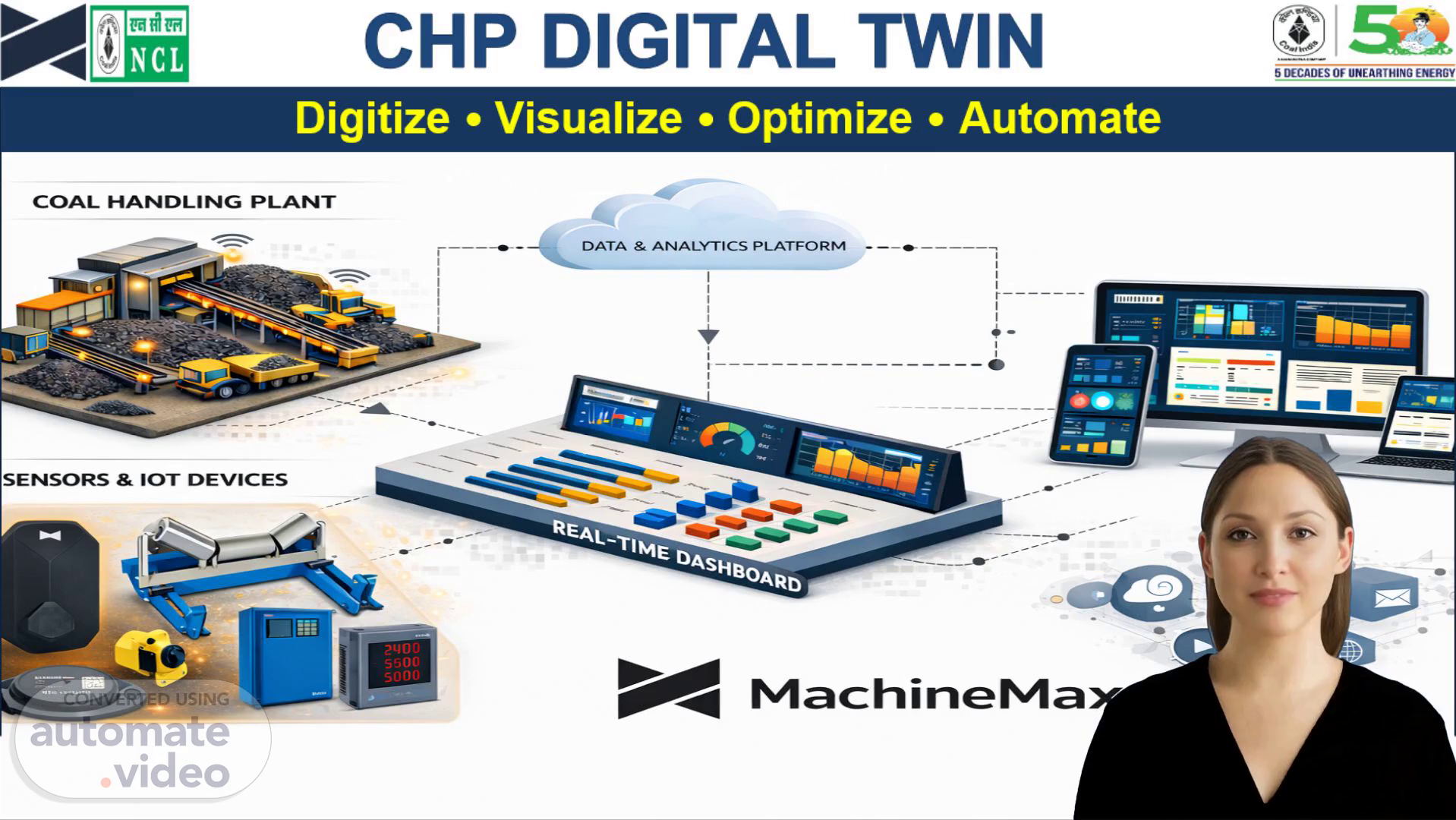

A computer with a headset and a mouse. A black background with blue letters AI-generated content may be incorrect. A green and white rectangular sign with white text AI-generated content may be incorrect. CHP DIGITAL TWIN.

Scene 4 (1m 5s)

[Audio] ## Step 1: Identify the main topic The main topic appears to be about IoT sensors installed at Khadia. ## Step 2: Analyze the given information The text mentions that the sensors are strategically placed for maximum efficiency and coverage. ## Step 3: Determine the purpose of the placement The placement of the sensors seems to be crucial for the overall operation, ensuring optimal performance and effectiveness. ## Step 4: Consider potential implications The strategic placement of the sensors may have significant implications for the operation's success and outcomes. ## Step 5: Evaluate the importance of the placement The placement of the sensors is vital for achieving the desired results and maximizing efficiency. ## Step 6: Assess the relevance of the placement The placement of the sensors is highly relevant to the operation's goals and objectives. ## Step 7: Draw conclusions based on the analysis Based on the analysis, it can be concluded that the placement of the sensors is critical for the operation's success. ## Step 8: Summarize the findings In summary, the placement of the IoT sensors at Khadia is essential for achieving maximum efficiency and coverage. ## Step 9: Provide recommendations It is recommended that the placement of the sensors be carefully monitored and adjusted as needed to ensure optimal performance. ## Step 10: Offer final thoughts Ultimately, the successful deployment of the IoT sensors will depend on their effective placement and maintenance..

Scene 5 (2m 57s)

[Audio] The digital twin platform provides advanced analytics and real-time monitoring capabilities. Our digital twin platform offers a range of tools and functionalities that enable users to gain insights into their operations and optimize their performance. One key feature is the ability to navigate through various reports and templates, such as the daily summary report and breakdown template. Additionally, users can access individual site overviews and download specific line performance data. Furthermore, the platform allows users to input manual data and track progress over time. With its user-friendly interface, our digital twin platform makes it easy for users to understand and analyze their data. By leveraging these features, users can identify areas for improvement and make data-driven decisions to optimize their operations..

Scene 6 (3m 53s)

[Audio] The digital twin technology allows for real-time monitoring and analysis of the plant's operations. Real-time monitoring enables the optimization of plant operations by identifying areas where improvements are needed. Analysis of operational data helps identify trends and patterns that may not be immediately apparent. This information can then be used to make informed decisions regarding the operation of the digital twin..

Scene 7 (4m 21s)

[Audio] The CHP Digital Twin platform provides real-time monitoring and control capabilities for all equipment within the facility. Users can easily access detailed information about each piece of equipment, including current performance metrics such as total power hours and totalizer readings. The platform also offers real-time tracking of key performance indicators, which enables swift decision-making and optimized operations. Organizations that utilize the CHP Digital Twin can improve their overall efficiency and productivity by leveraging its advanced features..

Scene 8 (5m 0s)

[Audio] The equipment has been thoroughly monitored and analyzed to ensure optimal performance and longevity. Detailed reports provide insights into current conditions and potential issues, enabling proactive maintenance and minimizing downtime. Regular monitoring helps identify trends and patterns, allowing for data-driven decisions to optimize equipment health. This comprehensive analysis enables informed decision-making, ensuring the continued reliability and efficiency of the equipment. By leveraging advanced technologies, we can accurately detect anomalies and predict future needs, facilitating efficient maintenance and reducing costs. The goal is to maintain peak performance and extend the lifespan of the equipment, while also improving overall operational efficiency..

Scene 9 (5m 54s)

[Audio] The presentation has concluded. All key data and insights from our digital twin project have been presented. Various applications and use cases have been explored. A digital twin has provided valuable information on equipment performance, health parameters, and operational efficiency. The data will be monitored and analyzed to optimize processes and improve overall performance..

Scene 10 (6m 20s)

[Audio] The silo lines average TPH comparison report provides a comprehensive overview of the average throughput of each silo line. The report highlights key statistics such as the average TPH, total volume, and percentage of capacity utilization. These statistics are essential for understanding the performance of each silo line and identifying areas for improvement. The report also includes data on the number of trains that have been loaded and unloaded at each silo line, providing valuable insights into the operational efficiency of each facility. The report provides a detailed analysis of the average TPH for each silo line, including the top five silo lines with the highest average TPH. The report also includes data on the total volume of goods transported through each silo line, which helps to identify trends and patterns in the transportation process. Additionally, the report provides information on the percentage of capacity utilization for each silo line, allowing users to evaluate the overall performance of each facility. The report offers several benefits to users, including improved decision-making, enhanced operational efficiency, and increased productivity. By analyzing the average TPH and other key statistics, users can gain a better understanding of their silo lines' performance and make informed decisions about how to optimize their operations. Furthermore, the report provides actionable recommendations for improving the efficiency of each silo line, helping users to achieve their goals and objectives..

Scene 11 (8m 2s)

A black background with blue letters AI-generated content may be incorrect. A green and white rectangular sign with white text AI-generated content may be incorrect. CHP DIGITAL TWIN.

Scene 12 (8m 16s)

A black background with blue letters AI-generated content may be incorrect. A green and white rectangular sign with white text AI-generated content may be incorrect. CHP DIGITAL TWIN.

Scene 13 (8m 31s)

A black background with blue letters AI-generated content may be incorrect. A green and white rectangular sign with white text AI-generated content may be incorrect. CHP DIGITAL TWIN.

Scene 14 (8m 46s)

A black background with blue letters AI-generated content may be incorrect. A green and white rectangular sign with white text AI-generated content may be incorrect. CHP DIGITAL TWIN.

Scene 15 (8m 59s)

A black background with blue letters AI-generated content may be incorrect. A green and white rectangular sign with white text AI-generated content may be incorrect. CHP DIGITAL TWIN.

Scene 16 (9m 6s)

[Audio] The system has been designed to monitor and report on various parameters, including current, temperature, and vibration levels. This allows for proactive maintenance and minimizes downtime. The alerts provided by the system enable operators to take swift action when issues arise, ensuring optimal performance and efficiency. By leveraging this digital twin technology, we can optimize equipment health and extend its lifespan. Regular monitoring and analysis of these parameters will help identify potential problems early on, allowing us to address them before they become major issues. This proactive approach enables us to maintain our equipment in top condition, reducing the risk of unexpected failures and associated costs..

Scene 17 (9m 54s)

[Audio] The system provides alerts based on specific operational parameters, ensuring optimal performance and minimizing downtime. These alerts can be categorized into three main types: idle, low load, and high load. The system monitors these parameters continuously, providing timely notifications when they exceed predetermined thresholds. This proactive approach enables swift action to be taken, preventing potential issues from escalating into major problems. By leveraging this advanced technology, organizations can ensure their equipment operates within designated parameters, resulting in improved efficiency and reduced maintenance costs..

Scene 18 (10m 39s)

[Audio] The company has developed a digital twin technology that allows it to monitor its physical assets remotely. The digital twin is a virtual replica of the physical asset, which can be used to analyze its performance in real time. The company uses this technology to monitor its equipment and machinery, and to detect any potential problems early on. The digital twin also provides real-time data on the condition of the equipment, including information about temperature, vibration, and other factors that could affect its performance. The company has implemented a system to alert users via WhatsApp whenever there is an issue with the equipment..

Scene 19 (11m 20s)

Thank You for Your Attention.